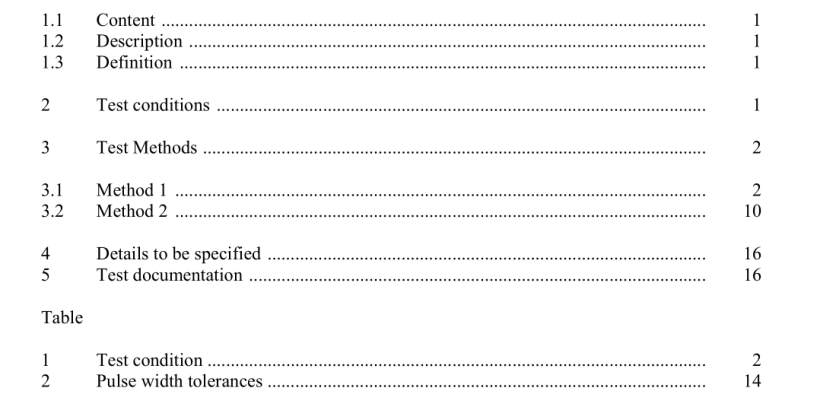

ANSI EIA 364-87B-2017 pdf download.Nanosecond Event Detection Test Procedure for Electrical Connectors, Contacts and Sockets

3.1.1.1.3.2 RF input impedance

A Time Domain Reflectometer (TDR) or Network Analyzer Time Domain Reflectometer (NATDR) shall be used to measure the reflection in percent of a (simulated) 0.5 nanosecond risetime step when the specimen direct current resistance is 10 ohms and the detector current is 100 milliamperes. (The 10 ohm specimen resistance is put on the bias port for NATDR.) An acceptable detector shall reflect less than 30% amplitude.

3.1.1.1.4 Amplitude sensitivity

Amplitude required to trip the detector with a 1 nanosecond duration pulse shall be no more than 120% of the direct current trip amplitude. One nanosecond pulse duration shall be measured at 90% of the pulse amplitude, and the rise and fall times shall be less than 0.5 nanosecond. Pulse low level shall be zero volts. These shall be measured with a 1 gigahertz minimum bandwidth oscilloscope and a pulse generator; see figure 1.

3.1.3.1.2 The specimen, as wired to the miniature coaxial cable for testing, shall be capable of passing short duration pulses. A time domain reflectometer (TDR) shall be used to measure the transition time of a fast risetime step (<60 ps) reflected from the specimen under test. On the waveform, find the point representing the far end of the miniature 50 ohm coaxial cable; see figure 3, Point 1. Also find the last point on the waveform where the voltage amplitude is 20% of Point 1; see figure 3, Point 2. Each series wired specimen circuit shall be measured. A typical plot of the wired specimen shall be supplied in the test report.

3.1.3.1.3 The time difference between Points 1 and 2 shall be less than the minimum duration specified in table 1. Example, if a 10ns event is specified, the calibration plot must be less than 10 ns, (Point 1 to Point 2). If this distance is greater than 10 ns, the event that can be detected will be equal to or greater than the value determined on the calibration plot. In this instance the requirement may have to be reevaluated.

3.1.3.2.1 EMI couples to the specimen through the parasitic capacitance between the specimen and any metal fixturing. An optional strategy to greatly reduce this coupling, and thereby reduce the risk of false trips due to EMI, is to connect the miniature coaxial cable shield to the metal fixturing. This optional connection is most effective if the connection is as short as possible and is perpendicular to nearby specimen conductors; see figure 2, note D. This optional connection is applicable to the specimen channel(s) only, not the control channel(s) with the EMI loop(s). NOTE ¾ If there is no metal fixturing within 5 cm of the specimen circuit, EMI coupling to the specimen through parasitic capacitance is not expected to be significant, so the optional connection of the miniature coaxial cable shield to the metal fixturing is not expected to be beneficial in reducing incidence of false trips due to EMI.

3.1.3.2.2 Large EMI currents in adjacent contacts can couple through crosstalk or capacitance to monitored channels. To reduce this, no conductor of any type may be connected to contacts not being monitored for an event. It is recommended that monitored contacts be evenly distributed around the connector to minimize crosstalk with other monitored channels; see figure 2, note B.

3.1.3.3 Control channel(s)

Anytime a failure is indicated, it is possible that the real cause was actually electromagnetic interference (EMI), and not the connector-under-test. The goal of the control channel(s) is to detect EMI at levels much lower than required to trigger an event on a specimen channel. During testing, the control channels shall be monitored with the same detector values as used on the specimen circuits. An event observed on a control channel invalidates any other events detected during the polling period, see 3.1.4.6 to define polling period.ANSI EIA 364-87B-2017 pdf download