ANSI BHMA A156.8-2000 pdf download.AMERICAN NATIONAL STANDARD FOR CDOOR CONTROL – OVERHEADS TOPS AND HOLDERS

2.1 Test Procedures

2.1.1 All tests shall be performed on doors 36 inx 84 inx 1-3/4 in (914 mm x 2134 mm x 44 mm) of either wood or metal and weighing 150 lbs (68 kg). Use metal frames of heavy enough construction to withstand the abuse required by these tests. The center of gravity of the weighted door shall be 18 in (457 mm) from the center line of hinge or pivot.

2.1.2 Means for mechanically opening the door to the stop position and releasing and closing the door shall be provided for the tests. Opening speed shall be 0 to 90 degrees in 3 to 6 seconds.

2.1.3 Doors shall be hung on heavy weight ball bearing hinges or pivots meeting Grade 1 requirements of ANSI/BHMA A156.1 for Butts and Hinges. Force required to overcome friction or out of balance condition shall be a 1/4 lbf(1.1 N) or less measured in accordance with paragraph 2.1.4.

2.1.4 All forces shall be applied to the door and readings shall be taken at a point 30 in (762 mm) from center line of hinge or pivot at a height of 40 in (1016 mm) from the bottom of the door.

2.2 Cycle Test

2.2.1 Single Point Adjustable Hold Open Types.

Door holders with a single point hold open function shall be adjusted to withstand a minimum of a 15 lbf (67 N) perpendicular to door in direction of closing, without releasing. Doors shall be mechanically pushed or pulled into hold open, and pulled or pushed back to a closed position for the requirements specified in 2.2.6. Adjustment shall be checked at 1/2 the total cycles required and readjusted to the 15 lbf (67 N), if necessary. At the end of the test, the force required to close the door shall be not less than a 10 lbf (44 N) or more than a 20 lbf (89 N) and shall be capable of readjustment to a 15 lbf(67 N).

2.2.2 Single Point Non-Adjustable Hold Open Types.

Door holders shall be capable of withstanding a minimum ofa 15 lbf (67 N) perpendicular to the door in the direction of closing without releasing at the start of the test. Doors shall be mechanically pushed or pulled into hold open and pulled or pushed back to a closed position for the requirements specified in 2.2.6. At the end of one half the cycling period, they shall have a minimum holding force ofa 10 lbf(44 N). At the conclusion of the cycle test they shall not have lost more than 50% of the original holding force.

2.2.3 Positive Type Holders less Automatic Release Feature.

Doors shall be mechanically pushed or pulled into hold open and mechanically released and closed for the requirements specified in 2.2.6.

2.2.4 Friction Slide Type Holders.

Frictional holders shall be adjusted to resist an 8 lbf (36 N) and readjusted to an 8 lbf (36 N) at the end of cach 10,000 cycles. At the end of the test, holder shall be capable of readjustment to resist an 8 lbf (36 N) without the necessity of renewing the friction unit. Apparatus shall operate at a 15 second cycle土2 seconds. Total cycle test for the friction holders is specified in 2.2.6.

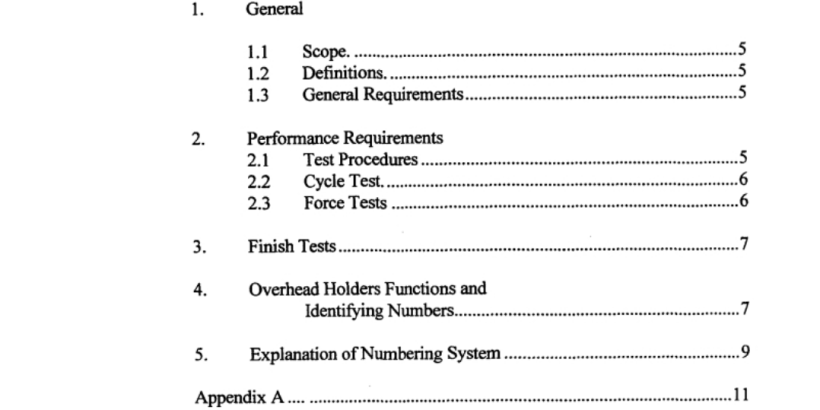

5.EXPLANATION OF NUM IBERING SYSTEM

First letter denotes the BHMA organizational Section (C)

First numeral indicates general type of material used:

O – Optional material

Second numeral identifies the type of product:

Type 1 – Overhead Concealed Slide Type – single or double acting, exterior or interior doors.

Type 2 – Overhead Surface Slide Type – single acting, exterior or interior doors.

Type 3 – Overhead Surface Jointed Arm – single acting, exterior or interior doors.

Type 4 – Overhead Concealed Slide Type – single or double acting, interior doors.

Type 5 – Overhead Surface Slide Type -single acting, interior doors.

Type 6- Overhead Concealed Slide Type – single or double acting, light interior doors.

Type 7 – Overhead Surface Slide Type -single acting, light interior doors.

Type 8 – Overhead Surface Rod Type – single acting, exterior or interior doors.

Type 9 – Overhead Surface Other Types – single acting, exterior or interior doors.ANSI BHMA A156.8-2000 pdf download