ANSI BHMA A156.18-2000 pdf download.AMERICAN NATIONAL STANDARD FOR MATERIALS AND FINISHES

3.1.2 Components without surfaces which are compatible with the prescribed test methods, shall use a finished flat test panel using substrate of the same base material of the actual product or component. The flat x 95 mm) and shall be 0,064 f 0.004 in (1.6 f panels shall have a minimum exposed area of 2.50 x 3.75 in (64 0.1 mm) thick. other materials are permitted to be specified by the affected ANSI Al 56 product standards.

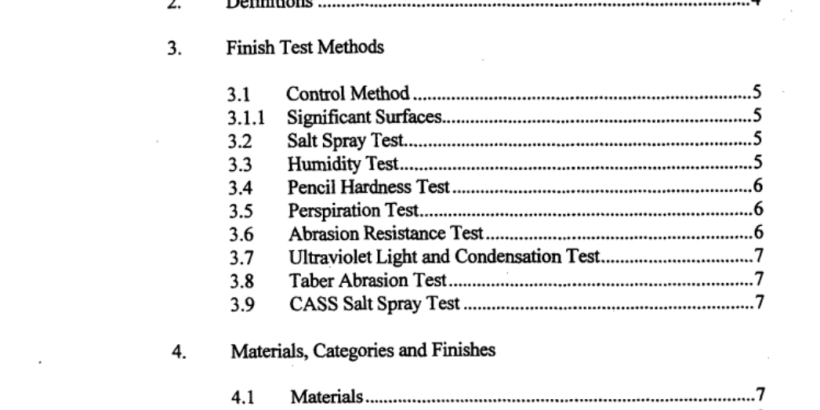

3.2 Salt Spray Test.

This test shall be conducted in accordance with ASTM B 1 17‑95 Standard Method of Salt Spray (Fog) Testing. Parts shall withstand exposure for the time specified in the applicable ANSVBHMA A156 Series Standard without base material or substrate corrosion exceeding one spot visible to the unaided eye per one square inch (25.4 square mm) of significant surface and without any spot larger than 1/16 in (1.6 mm) in diameter. Staining shall not exceed 5% of the significant surface area of the 114 in. (6.4 mm) in diameter. component under test and without any spot larger than 5% relative humidity at 100

3.3 Humidity Test.

This test shall be conducted in a chamber having a 95% f 5 degrees (38 degrees C f 3 degrees) for the times specified in the applicable ANSI/BHMA degrees F f A 156 Series Standard. The parts shall be allowed to stabilize at room temperature for 30 minutes before they are examined. Blistering or staining of the part shall not be visible to the unaided eye. The coating shall, within an additional 15 minutes, pass a pencil hardness test (see 3.4) as specified in the applicable ANSVBHMA A156 Series Standard and shall pass the method B Cross‑Cut Tape Test as defined in ASTM D 3359‑95A Method for Measuring Adhesion by Tape Test. The rating shall be as specified in the applicable ANSVBHMA A156 Series Standard.

3.5 Perspiration Test.

This test shall be conducted using a reagent made up by weight of 5% sodium chloride, 5% acetic acid, 3% butyric acid, 3% valeric acid and 84% distilled water which is less than one year old and has been stored at 40 degree F+5 degrees F (4 degrees C+3 degrees C). An epoxy dam shall be used to contain the solution over an area between % and 1 square in. (323 and 645 square mm) with a minimum solution depth of 1/16 in. (1.6 mm). Apply the reagent; let stand for 15 minutes and wash off with cold water. The coating shall then pass a pencil hardness test in accordance with 3.4 using a pencil lead of 2B hardness. This constitutes one cycle. Repeat on the same area the number of cycles specified in the applicable ANSI/BHMA A156 Series Standard. 3.6 Abrasion Resistance Test. The surface of protective or decorative surface treatments shall be subjected to the Abrasion Resistance Test in accordance with ASTM D968-93 Test Method for Abrasion Resistance of Organic Coatings by Falling Abrasive. The quantity of falling sand or silicon carbide and other values shall be as specified in the applicable ANSI/BHMA A156 Series Standard.

3.7 Ultraviolet Light and Condensation Test. This test shall be conducted in accordance with ASTM G 53‑96 Standard Recommended Practice for Operating Light and Water Exposure Apparatus (Fluorescent UV‑Condensation Type) for Exposure of Nonmetallic Materiais except as follows. For products having only interior exposure, use UVA‑351 lamps. For all other products, use UVA‑340 lamps. The test cycles and Three test specimens shall be duration shall be specified in the applicable ANSIIBHMA A156 Series Standards. tested for each finish and one additional specimen shall be retained for comparison at the end of the test. For coatings used on multiple base materials, testing of only one material is required. The retained specimen shall be stored in a controlled environment and protected fiom UV exposure. Start the test at the beginning of a Wcycle and end it at the conclusion of a condensation cycle. ANSI BHMA A156.18-2000 pdf download