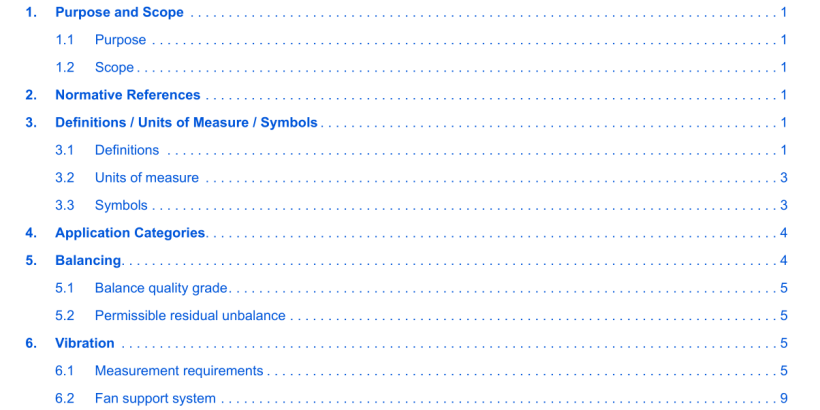

ANSI AMCA 204-05-R2012 pdf download.Balance Quality and Vibration Levels for Fans

1.2 Scope

This standard covers fans with rigid rotors, generally found in commercial heating, ventilating and air conditioning; indus- trial process applications; mine/tunnel ventilation applica- tions, and power generation applications. Other applications are not specifcally excluded, except as follows: Excluded are installations that involve severe forces, impacts, or extreme temperature acting on the fan. Fan foundations and installation practices are beyond the scope of this standard. Foundation design and fan installa- tion are not normally the responsibilities of the fan manufac- turer. It is fully expected that the foundation upon which the fan is mounted will provide the support and stability neces- sary to meet the vibration criteria of the fan as it is delivered from the factory. Other factors such as impeller cleanliness, aerodynamic conditions, background vibration, operation at rotational speeds other than those agreed upon, and maintenance of the fan affect fan vibration level but are beyond the scope of this standard. This standard is intended to cover only the balance or vibra- tion of the fan and does not take into account the effect of fan vibration on personnel, equipment, or processes. Any or all portions of this standard, or modifcations thereof, are subject to agreement between the concerned parties.

3.1.12 Flexible support

A fan support system designed so that the frst natural frequency of the support is well below the frequency corre- sponding to the operating rotational speed of the fan. Often this involves compliant elastic elements between the fan and the support structure. “This condition is achieved by suspending the machine on a spring or by mounting on an elastic support (springs, rubber, etc.). The natural oscilla- tion frequencies of the suspension and machine is typically less than 25% of the frequency corresponding to the lowest speed of the machine under test”—-NEMA MG 1-1993, Rev. 1, Part 7, Section 7.06.1.

3.1.22 Rigid support

A fan support system designed so that the frst natural frequency of the system is well above the frequency corre- sponding to the operating rotational speed of the fan. “Note: The rigidity of a foundation is a relative quantity. It must be considered in conjunction with the rigidity of the machine bearing system. The ratio of bearing housing vibration to foundation vibration is a characteristic quantity for the evaluation of foundation fexibility infuences. A foundation may be considered massive if the vibration amplitude of the foundation (in any direction) near the machine’s feet or base frame are less than 25% of the maximum amplitude that is measured at the adjacent bearing housing in any direction.” —-NEMA MG1-1993, Rev. 1, Part 7, Section 7.06.2.

4. Application Categories

The design/structure of a fan and its intended application are important criteria for categorizing the many types of fans in terms of applicable and meaningful balance quality grades and vibration levels. Table 4.1 categorizes fans by their application and driver power to arrive at appropriate Balance and Vibration (BV) application categories. A fan manufacturer will typically identify the appropriate application category based on the type of fan and power. A purchaser of a complete fan assembly may be interested in one or more of the following: the Balance Grade (Table 5.1), vibration as tested in the factory (Table 6.2), or vibra- tion in-situ (Table 6.3). Typically, one Balance and Vibration category will cover both the application and the driver power considerations. However, a purchaser may request a Balance and Vibration category different from the one listed for the application and driver power considerations. Some may desire a more precise balance quality grade or lower vibration level than is typical for the application. In most cases, the Balance and Vibration category, the balance quality grade and vibration limits must be agreed upon as part of the contract for the fan. In the event that no such agreement exists, fans purchased as being required to comply with this standard shall meet the Table 6.2 vibration limits (assembled fan) or the Table 5.1 residual unbalance requirements (unassembled fan or rotor assembly only). The purchaser may contract for a particular mounting arrangement to be used for factory testing of an assembled fan in order to match (as nearly as possible) the planned in-situ mounting at the job site. If no specifc contract on balance/vibration exists, the fan may be mounted either rigidly or fexibly for the test, regardless of the in-situ mounting.ANSI AMCA 204-05-R2012 pdf download