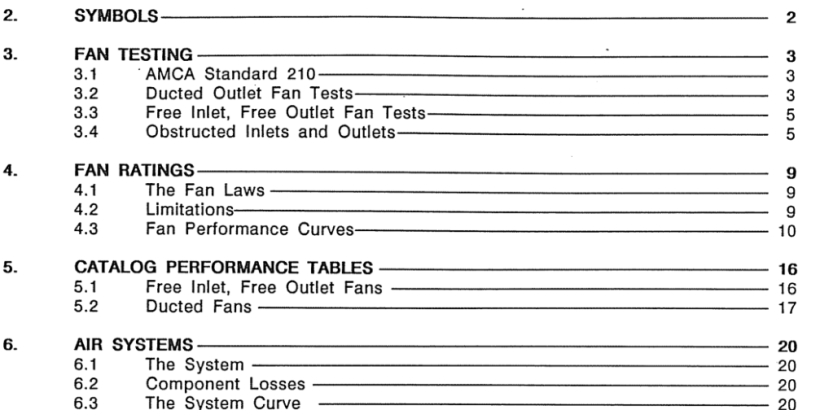

ANSI AMCA 201-1990 pdf download.FANS AND SYSTEMS

3.1 AMCA STANDARD 210

Most fan manufacturers rate the performance of their products from tests made in accordance with AMCA Standard 210, Laboratory Methods of Testing Fans for Rating. The purpose of Standard 210 is to establish uniform methods for laboratory testing of fans and other air moving devices to determine performance in terms of flow rate, pressure, power, air density, speed of rotation and efficiency, for rating or guarantee purposes. Two basic methods of measuring air flow are included–the pitot tube and the long radius flow nozzle. These are incorporated into a number of different “setups” or “figures.” In general, a fan is , tested on the setup which most closely simulates the way in which it will be installed in an air moving system. Centrifugal, tubeaxial and vaneaxial fans are usu- ally tested with an outlet duct. Propeller fans are normally tested in the wall of a chamber or plenum. Power roof exhausters are tested mounted on a curb exhausting from the test chamber. It is very important to realize that each setup in AMCA Standard 210 is a standardized arrangement which is not’ intended to reproduce exactly any installation likely to be found in the field. The infinite variety of possible arrangements of actual air systems makes it impossible to duplicate these in the fan test laboratory.

3.2 DUCTED OUTLET FAN TESTS

Figure 3-2 is a reproduction of a test setup from AMCA Standard 210. Note that this particular setup includes a long straight duct connected to the outlet of the fan. A straightener is located upstream of the pitot traverse to remove swirl and rotational components from the air flow and to ensure that the flow at the plane of measurement is as near to uniform as possible. The angle of the transition between the test duct and the fan outlet is limited to ensure that uniform flow will be maintained. A steep transition, or abrupt change of cross-section would cause turbu- lence and eddies, and lead to non-uniform flow. The effect of this type of flow disturbance at the fan outlet is discussed later. Uniform flow conditions ensure consistency and reproducibility of test results and permits the fan to develop its maximum performance. In any installation where uniform flow conditions do not exist the fan’s performance will be reduced.

The velocity profile at the outlet of a fan is not uni- form. This is ilustrated in Figure 3-3 Plane 2. The section of straight duct attached to the fan out- let ‘controls the diffusion of the non-uniform outlet flow and establishes a more uniform velocity pro- file before discharging into a plenum chamber or to the atmosphere as shown in Figure 3-3 Plane X. The energy loss when a gas passes through a sud- den enlargement is related to the square of the velocity. Thus the ducted outlet with its more uni- form velocity significantly reduces the loss at the point of discharge to atmosphere. A manufacturer may test a fan with or without an outlet duct or inlet duct. For products licensed to use the AMCA Seal, catalog. ratings will state whether ducts were used during the rating tests. If the fans are not to be applied with the same ducts as in the test setup an allowance should be made for the difference in performance which may result.ANSI AMCA 201-1990 pdf download