ANSI B71.7-2018 pdf download.for Powered Consumer Ram-Type Log Splitters – Safety Specifications

Power may be supplied by an internal-combustion engine or an electric motor. These specifications are intended to provide safety requirements and to help ensure uniform operator environments. They are intended to apply to products specifically intended as consumer products for the personal use of a consumer around the home. This standard applies to all aftermarket parts, attachments, and accessories. Any manufacturer of aftermarket parts, attachments and accessories is responsible for ensuring compliance to this standard. Safety specifications in this standard apply only to a configuration of attachments/implements/accessories approved by their respective manufacturers. These specifications are not intended to apply to commercial products customarily used by hired operators or to products designed primarily for agricultural purposes such as those defined in SAE J1 1 1 6 or three- point hitch mounted machines. The effective implementation date of this standard shall be two (2) years after the publication date and shall apply to all products built after that date. Manufacturers may also comply with the requirements of this standard anytime after the publication date.

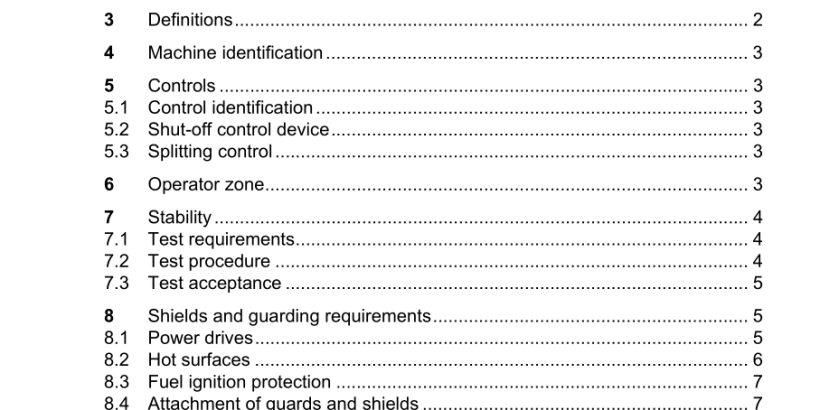

8.2.2 Test procedure

The test shall be conducted in the shade with a wind speed not to exceed 3 m/s (6.7 mi/h). The engine shall be operated at its maximum operating engine speed until the surface temperatures stabilize. Temperatures shall be determined by correcting the observed temperature by the difference between 20°C (68°F) and the ambient test temperature. When the distance between the identified hot area and the nearest control is in excess of 1 00 mm (3.9 in), cone A as shown in Figure 5 shall be used. For distances less than or equal to 1 00 mm (3.9 in) between the identified hot area and the nearest control, cone B in Figure 5 shall be used. For cone A, with the axis of the cone anywhere between 0 and 1 80° to the horizontal and with the nose or point of the cone in a downward to horizontal direction, move the cone towards the hot surface. The nose of the cone shall not be pointed in an upward direction. When moving the cone, determine if contact is made with the hot surface area(s) with the cone tip or conical surface of the cone. Cone B shall be used with the axis of the cone in any direction and moved in any direction. It is not necessary to test the accessibility of hot parts while they are hot. Allow the hot parts to cool before using the cone(s). All guards shall be in their normal operating position during this test.

8.5 Pressurized hoses

Where hoses are operating at a maximum working pressure greater than 5000 kPa (725 psi) and are located within 500 mm (20 in) of the operator zone, they shall be located or shielded so that, in the event of a rupture, the fluid cannot be discharged directly on to the operator when in the normal operating position. The same requirements apply to hoses operating at a maximum working pressure of 500 kPa (73 psi) to 5000 kPa (725 psi) and where the temperature of the pressurized fluid exceeds 50°C (1 22°F) when operated at an ambient temperature of 20°C ± 5°C (68°F ± 9°F). Compliance to be checked by inspection and measurement.

9.2 The operator’s, service, and maintenance instructions shall contain:

a) information that hydraulic fluid escaping under pressure may have sufficient force to penetrate skin and cause serious injury, and that if foreign fluid is injected into the skin, it must be surgically removed within a few hours by a doctor familiar with this form of injury, or gangrene may result;

b) a warning to keep body and hands away from pinholes or nozzles that eject hydraulic fluid under high pressure, and to use paper or cardboard and not hands to search for leaks;

c) information explaining how to safely relieve all pressure in the system before disconnecting the lines or performing work on the system; and

d) a warning to make sure all hydraulic fluid connections are tight and all hydraulic hoses and lines are in good condition before applying pressure to the system.ANSI B71.7-2018 pdf download