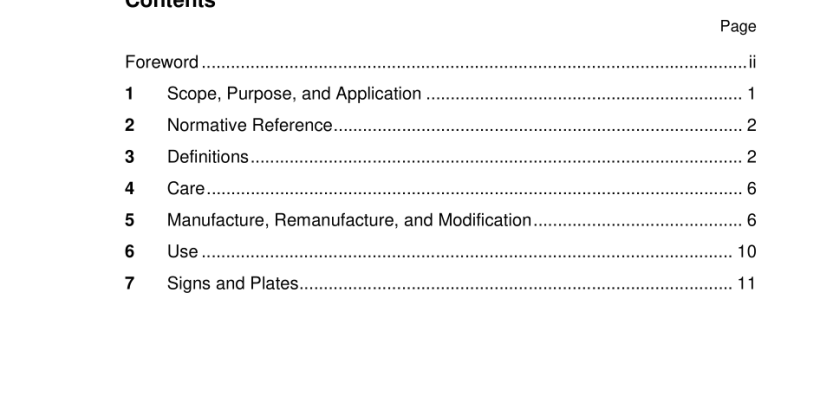

ANSI B151.5-2000 pdf download.for Plastic Film and Sheet Winding Machinery – Manufacture, Care and Use

1.3.1 New Installation

The requirements of this standard pertaining to manufacture shall apply to all new or remanufac- tured Machinery installed in the United States of America. Compliance shall be achieved within one year of the approval date of this standard. Date of shipment (month and year) shall be affixed to the Machine permanently and legibly along with the name of the manufacturer or remanufacturer.

1.3.2 Existing Installations

The employer is responsible for bringing existing Machines into compliance with the requirements of this standard within three years of the approval date of this standard. By the end of the three-year transition period, the 4- inch opening referred to in 5.3.1.1 shall be changed to 3 inches. It is not the intent of this standard to require exist- ing installations to be in total compliance with the latest revision of ANSI/NFPA 79-1997, Electrical Standard for Industrial Machinery. Only those re- quirements that address personnel safety require updating.

1.3.3 All Installations

An employer shall not operate a Machine or permit it to be operated unless it is in compliance with this standard.

2 Normative References

The following standards contain provisions which, through reference in this text, constitute provisions of this American National Standard. At the time of publication, the editions indicated were valid. All standards are subject to revision, and parties to agreements based on this American National Stan- dard are encouraged to investigate the possibility of applying the most recent edition of the standards indicated below.

5.2.1 Access Openings

Hazardous areas that are accessible shall be guarded. When the guard is not fixed, it shall be interlocked to stop hazardous motion exposed by moving or removing the guard. Where safeguarding of hazards is not technically or operationally feasi- ble these hazardous areas shall be color coded.

5.2.2 Rotating Shaft

Extension Rotating shaft extensions shall be smooth and shall not project more than one-half of the diameter of the shaft unless guarded. Smooth roll journals fitted with rotary joints and piping and presenting no sig- nificant hazard are excepted from these require- ments.

5.2.3 Cutting Devices

All web-cutting devices within the reach point dur- ing normal production operation shall be guarded to the extent technically and operationally feasible. A means shall be provided to prevent unintentional movement during thread-up, blade change, or other adjustment. Blade holders shall be color-coded and a safety sign shall be provided.

5.3 Guarding, Nips

5.3.1 Counter-Rotating Nips

The inrunning side of the counter-rotating nips within the operator’s reach point shall be guarded to prevent a person from being caught in the nips and shall have an Emergency Stop Device readily accessible to that person. The guard shall not form a wedging nip.

5.3.1.2 Nip Roll Closing

If operator-accessible nip rolls are closed by local control, no alarm or delay is required. If local con- trol is not used, then a local preclose alarm shall be used. The preclose alarm circuit shall be designed such that an alarm of three seconds duration sounds prior to immediate roll closing. Exception: If the nip created by the closing rolls is in full view of the roll close control device, the rolls may be opened and reclosed within a period of 5 seconds without the local preclose alarm. However, the alarm shall be active from the time the rolls are opened until they close.

5.3.1.4 Independently Moveable Guards

Where guard motion is independent of roll move- ment, the guard shall be interlocked to prevent clos- ing of the rolls when the guard is not in place and shall open the roll if the guard is withdrawn from its effective position. Closing of the guard shall not of itself cause the rolls to close. Rotation of the rolls is permitted with the rolls open independent of guarding. See 5.3.1.2.ANSI B151.5-2000 pdf download