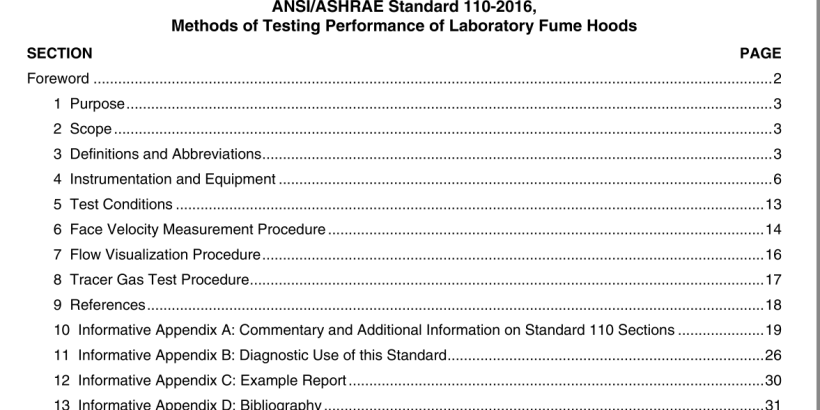

ANSI ASHRAE 110-2016 pdf download.Methods of Testing Performance of Laboratory Fume Hoods

auxiliary air: unconditioned or partially conditioned supply or supplemental air delivered to a laboratory at the laboratory fume hood to reduce room air consumption. control level: the average measured concentration of tracer gas, in parts of tracer gas per million parts of air by volume (ppm) that is not exceeded at the hood face with a 4.0 Lpm (67 mL/s) release rate. design opening: the position of the sash at which the design team assumes that the hood will be operating. The design opening is critical for determining the volumetric flow through the laboratory hood. face velocity: the average velocity of air moving perpendicu- lar to the hood face, usually expressed in feet per minute (fpm) or meters per second (m/s).

fume hood system: an arrangement consisting of a fume hood, its adjacent room environment, and the air exhaust equipment, such as blowers and ductwork, required to make the hood operable. hood face: the plane of minimum area at the front portion of a laboratory fume hood through which air enters when the sash is or sashes are full opened, usually in the same plane as the sash for a hood with a vertical sash. For hoods with horizontal sashes, combination sashes, or multiple vertical sashes, the hood face is the plane corresponding to the surface of the outer-most sash panel. laboratory hood (sometimes referred to as a fume hood): a box-like structure enclosing a source of potential air contami- nation, with one open or partially open side, into which air is moved for the purpose of containing and exhausting air con- taminants. A laboratory hood is generally used for bench-scale laboratory operations but does not necessarily involve the use of a bench or table. Figure 3.1 shows the major components of a typical laboratory hood. Although the test in this standard is written for a benchtop laboratory hood, other applications are discussed in Informative Appendix A. lazy airflow: an airflow problem in a hood that is revealed when the smoke generated in a smoke challenge remains on the work surface without smoothly flowing to the back baffle. Figure 3.2 shows an example of lazy airflow. maximum opening: the position of the sash at which the hood has the largest opening.

where SME means “sash movement effect,” AM means “as manufactured,” AI means “as installed,” AU means “as used,” and yyy is the sash movement effect in ppm. A test rating of SME-AM 10, for example, indicates that the maximum 45- second, rolling-average concentration of tracer gas measured during a sash movement test under the “as manufactured” test, with a tracer gas release rate of 4.0 Lpm (67 mL/s) (as required in Section 4.1), is 10 ppm. specified rating: the hood performance rating as specified, proposed, or guaranteed either in the purchase of the hood or in the design and construction of the laboratory, or both. test opening: the position or positions of the sash(es) at which the hood is to be tested. Normally, the test opening is the design opening, the operating opening, or the maximum opening. Proper selection of the test opening will depend on both the design opening and the operating opening. Because of the time involved in doing multiple equipment setups, the test opening may also be the maximum opening. The specifi- cation shall identify the details of the test positions. An exam- ple of a specification for a combination sash hood could include three positions with the vertical sash closed and the horizontal windows placed at the left, center, and right. In addition, this hood may be tested with the vertical sash opened to a sash height determined by a sash stop. titanium tetrachloride: a chemical, TiCl 4 , used to generate the white visible fumes required for preliminary testing in laboratory hoods.ANSI ASHRAE 110-2016 pdf download