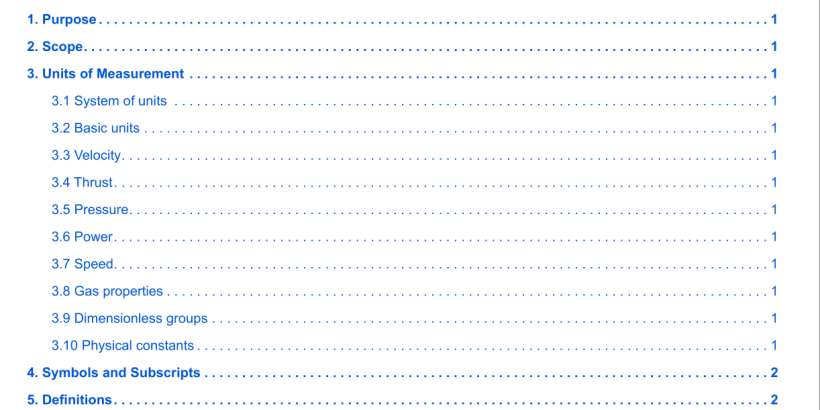

ANSI AMCA 230-2015 pdf download.Laboratory Methods of Testing Air Circulating Fans for Rating and Certification

2. Scope

This standard shall be used as the basis for testing air circulating fan heads, ceiling fans, box fans, table fans, portable personnel coolers or other air circulating devices when air is used as the test gas. The diameter of the fan being tested shall be limited by the minimum dimensions as shown in the applicable test fgures. Blowers, exhausters, compressors, positive displacement machines and positive pressure ventilators are not within the scope of this standard. The parties to a test for guarantee purposes shall agree on exceptions to this standard in writing prior to the test. However, only tests which do not violate any mandatory requirements of this standard shall be designated as tests conducted in accordance with this standard.

3.1 System of units

SI units (The International System of Units, Le Systéme International d’Unités) [1] are the primary units employed in this standard, with I-P units (inch-pound) given as the secondary reference. SI units are based on the funda- mental values of the International Bureau of Weights and Measures [1], and I-P values are based on the values of the National Institute of Standards and Technology, which are in turn based on the values of the International Bureau.

3.2 Basic units

The SI unit of length is the meter (m) or the millimeter (mm); the I-P unit of length is the foot (ft) or the inch (in.). The SI unit of mass is the kilogram (kg); the I-P unit of mass is the pound mass (lbm). The unit of time is either the minute (min) or the second (s). The SI unit of temperature is either the Kelvin (K) or the degree Celsius (°C); the I-P unit of temperature is either the degree Fahrenheit (°F) or the degree Rankine (°R). The SI unit of force is the newton (N); the I-P unit of force is the pound force (lbf).

6.1.2 Measurement uncertainty

It is axiomatic that every test measurement contains some error and that the true value cannot be known because the magnitude of the error cannot be determined exactly. However, it is possible to perform an uncertainties analysis to identify a range of values within which the true value probably lies. A probability of 95% has been chosen as acceptable for this standard. The standard deviation of random errors can be deter- mined by statistical analysis of repeated measurements. No statistical means are available to evaluate systematic errors, so these must be estimated. The estimated upper limit of a systematic error is called the systematic uncer- tainty and, if properly estimated, it will contain the true value 99% of the time. The two standard deviation limit of a random error has been selected as the random uncertainty. Two standard deviations yield 95% probability for random errors.

6.1.3 Uncertainty of a result

The results of a fan test are the various fan performance variables listed in Section 5.5. Each result is based on one or more measurements. The uncertainty in any result can be determined from the uncertainties in the measurement. It is best to determine the systematic uncertainty of the result and then the random uncertainty of the result before combining them into the total uncertainty of the result. This may provide clues on how to reduce the total uncertainty. When the systematic uncertainty is combined in quadrature with the random uncertainty, the total uncertainty will give 95% coverage. In most test situations, it is wise to perform a pre-test uncertainties analysis to identify potential prob- lems. A pre-test uncertainties analysis is not required for each test covered by this standard because it is recognized that most laboratory tests for rating are conducted in facili- ties where similar tests are repeatedly run. Nevertheless, a pre-test analysis is recommended as is a post-test analy- sis. The simplest form of analysis is a verifcation that all accuracy and calibration specifcations have been met. The most elaborate analysis would consider all the elemental sources of error including those due to calibration, data acquisition, data reduction, calculation assumptions, envi- ronmental effects and operational steadiness.ANSI AMCA 230-2015 pdf download