ANSI ADA AAMI ST55-2010 pdf download

ANSI ADA AAMI ST55-2010 pdf download.Table-top steam sterilizers

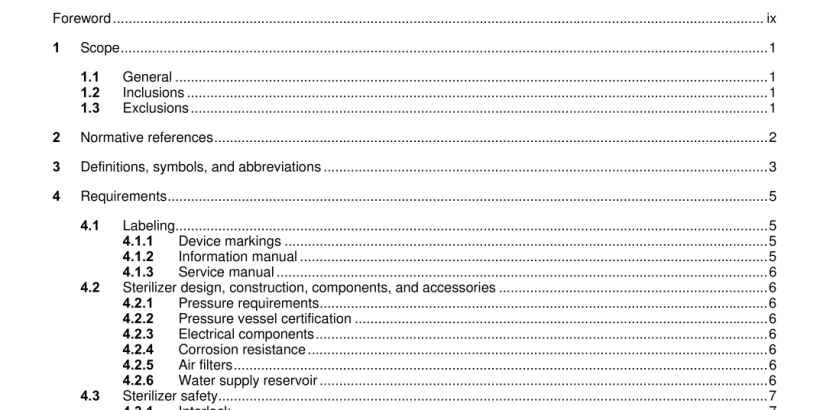

1 Scope

1.1 General This standard applies to steam sterilizers that are intended for use in health care facilities and that have a volume less than or equal to 56.63 liters (2 cubic feet [ft 3 ]). NOTE—For purposes of this standard, health care facilities refers to hospitals, nursing homes, extended-care facilities, freestanding surgical centers, clinics, and medical and dental offices. For convenience, the term hospital is sometimes used in this standard; in all instances, this term should be taken to encompass all other health care facilities.

1.2 Inclusions

This standard covers minimum labeling, safety, performance, and testing requirements for small steam sterilizers, including cassette sterilizers, that have a volume less than or equal to 56.63 liters (2 ft 3 ), have automatic controls, and provide means of controlling time and temperature. Definitions of terms and normative references are also included, as well as an annex explaining the rationale for the provisions of the standard and other informative annexes. NOTE—This standard is intended primarily for use by manufacturers in the performance and design qualification of table-top steam sterilizers that are intended for use in health care facilities. The criteria defined in this standard might be useful to health care personnel and purchasing authorities in the acquisition process. However, the standard is not intended to provide guidelines for receiving–inspection testing or steam sterilization procedures in health care facilities.

1.3 Exclusions

Manually controlled steam sterilizers (i.e., sterilizers without software control) and all other sterilizers not covered in 1 .2 are excluded from the scope of this standard. NOTE—Minimum labeling and performance requirements for large steam sterilizers (those having a volume greater than 56.63 liters [2 ft 3 ]) are covered in ANSI/AAMI ST8. Guidelines for steam sterilization procedures in health care facilities, including typical steam sterilization cycle parameters, are provided in ANSI/AAMI ST79.

4.2.1 Pressure requirements

All sterilizers that can be operated at pressures above atmospheric pressure, under normal or “fault” conditions, shall have a pressure-relief device. The design and the materials of construction of sterilizers intended to be operated at an internal pressure of 204.7 kPa absolute (1 5 psig) or more shall conform to the requirements of Section VIII, Division 1 , of the ASME Boiler and pressure vessel code in addition to the safety requirements of UL 61 01 0-1 and IEC 61 01 0-2- 040. The sterilizer manufacturer shall furnish proof of such conformance. For sterilizers whose pressure vessel design, materials, or construction are not covered by existing code rules in Section VIII, Division 1 , of the ASME Boiler and pressure vessel code, the sterilizer manufacturer shall furnish proof of pressure vessel safety relating to pressure integrity in accordance with UL 61 01 0-1 and IEC 61 01 0-2-040. Sterilizers intended to be operated at a pressure below 204.7 kPa absolute (1 5 psig) shall be designed and tested to withstand a pressure of 3 times the pressure relief setting. If steam is produced for the sterilizer by its own dedicated steam generator, the generator shall conform to applicable provisions of the ASME code. All sterilizers shall satisfy the local boiler and pressure vessel safety laws and regulations issued by the enforcement or regulatory bodies having jurisdiction at the location of installation.

4.2.6 Water supply reservoir

Means shall be provided to prevent cycle initiation unless sufficient water is present in the reservoir to properly complete a cycle. The sterilizer shall not allow ingress of water into the sterilization chamber after the holding time is complete. All sterilizers shall provide a means by which the water supply reservoir can be periodically drained and decontaminated. See also 4.1.2(e).