ANSI AAMI ST65-2008 pdf download

ANSI AAMI ST65-2008 pdf download.Processing of reusable surgical textiles for use in health care facilities

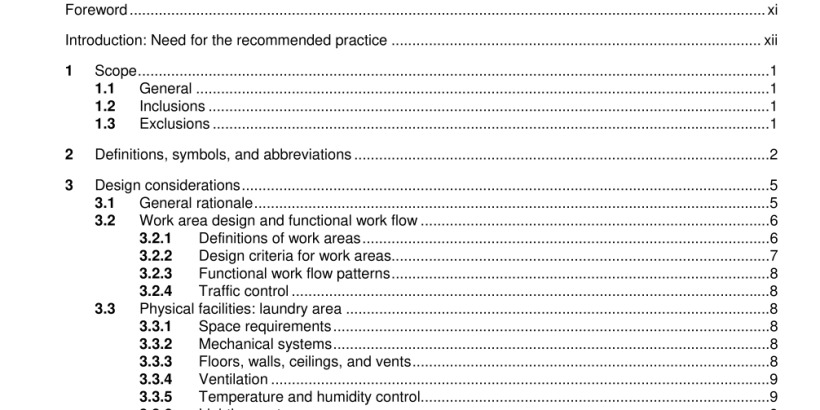

1.1 General

This recommended practice provides guidelines for properly handling, processing, and preparing reusable surgical textiles for use in health care facilities. These guidelines describe a quality assurance program for the processing of reusable surgical textiles, including processes and techniques for the preparation of clean bulk items for delivery to user sites and the assembly of textile packs for sterilization prior to end use. These guidelines apply to all facilities that process surgical textiles, whether on-premise laundries (OPLs), hospital-owned cooperatives, or commercial facilities. NOTE 1 —Surgical textiles labeled for single use only should not be reprocessed or reused, because it may not be possible to adequately reprocess them and maintain their performance and safety attributes. In addition, the health care facility’s liability may be affected if the manufacturer’s written instructions for use are not followed. See also FDA regulations applicable to the reprocessing of single-use medical devices (www.fda.gov/cdrh/reprocessing/). NOTE 2—For purposes of this recommended practice, “health care facility” means hospitals, nursing homes, extended care facilities, freestanding surgical centers, clinics, and medical, surgical, and dental offices. For convenience, the term “hospital” is sometimes used in this recommended practice; in all instances, the term should be taken to encompass all other health care facilities.

1.2 Inclusions

This recommended practice specifically addresses

a) design criteria for functional work areas involved with the receiving, staging, and handling of soiled surgical textiles; the separation of soiled and clean textiles; the laundering of reusable surgical textiles; and the inspection and preparation of clean bulk items and surgical textile packs;

b) staff qualifications, education, training, dress codes, and other personnel considerations;

c) transporting, receiving, and handling of both newly purchased and soiled surgical textiles;

d) laundry processing (loading, washing, drying) recommendations;

e) inspection, testing, and maintenance of laundered textiles;

f) preparation and packaging of laundered textiles;

g) handling, transport, and storage of laundered textiles;

h) installation, operation, care, and maintenance of laundry equipment;

i) quality control measures, procedures, and practices;

j) medical device regulatory considerations.

Definitions of terms and a bibliography are also provided in this recommended practice.

2.58 transmission-based precautions: Precautions designed for patients documented or suspected to be infected with highly transmissible or epidemiologically important pathogens for which additional precautions beyond standard precautions are used to interrupt transmission in hospitals. There are three types of transmission-based precautions: contact precautions, airborne precautions, and droplet precautions. NOTE—Transmission-based precautions are used in addition to standard precautions.

2.59 washing equipment: Machines used to wash textiles by exposing them directly to water, usually at elevated temperatures and with the addition of chemicals. There are several major types of washing equipment: continuous-batch washer: Washing machine that allows for a continuous flow of textiles through the process. This equipment uses a number of horizontal-axis modules (usually 7 to 1 6) placed in sequence, each of which has a predefined function (step in the washing process) for each formula used. The time in each module is usually set between 2 and 3 minutes, and the water is reused in a counterflow process (i.e. clean water enters the last module and is reused until it reaches the first module). These units are controlled by a microprocessor or card unit. home washers: Machines that allow for batch processing of textiles. This equipment usually is of a vertical-axis design and has standard (nonprogrammable) wash cycles. NOTE—This equipment is not appropriate for processing most types of health care textiles. See 6.1 . open-pocket/split-pocket washers: Washing machines that allow for batch processing of textiles. This equipment is typically of a horizontal-axis design, has an open or split compartment that allows the textiles and wash liquor to intermingle freely in the chamber, and is controlled either by a microprocessor or a card unit.