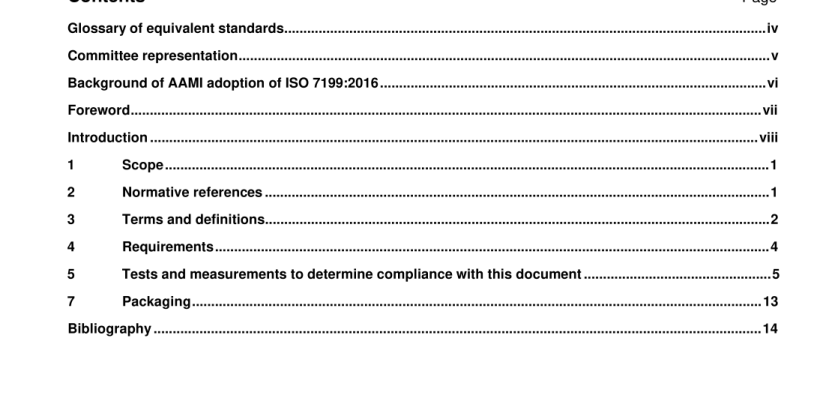

ANSI AAMI ISO 7199-2016 pdf download

ANSI AAMI ISO 7199-2016 pdf download.Cardiovascular implants and artificial organs — Blood-gas exchangers (oxygenators)

1 Scope

This document specifies requirements for sterile, single-use, extracorporeal blood-gas exchangers (oxygenators) intended for supply of oxygen to, and removal of carbon dioxide from, the blood of humans.

This document also applies to heat exchangers and arterial filters that are integral parts of the oxygenator.

This document also applies to external equipment unique to the use of the oxygenator.

This document does not apply to

— implanted oxygenators,

— liquid oxygenators,

— extracorporeal circuits (blood tubing),

— separate heat exchangers,

— separate ancillary devices, and

— separate arterial line filter.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1 0993-1 , Biological evaluation of medical devices — Part 1: Evaluation and testing within a risk management process

ISO 1 0993-4, Biological evaluation of medical devices — Part 4: Selection of tests for interaction with blood

ISO 1 0993-7, Biological evaluation of medical devices — Part 7: Ethylene oxide sterilization residuals

ISO 1 0993-1 1 , Biological evaluation of medical devices — Part 11: Tests for systemic toxicity

ISO 1 1 1 35, Sterilization of health-care products — Ethylene oxide — Requirements for the development, validation and routine control of a sterilization process for medical devices

ISO 1 1 1 37-1 , Sterilization of health care products — Radiation — Part 1: Requirements for development, validation and routine control of a sterilization process for medical devices

ISO 1 1 607-1 , Packaging for terminally sterilized medical devices — Part 1: Requirements for materials, sterile barrier systems and packaging systems

5.4.3.2 Procedure

Two sets of appropriate, identical circuit components, including a pump, connecting tubing, a reservoir (as specified by the manufacturer and of suitable size relative to the device under test) and a heat exchanger, shall be assembled. The device under test shall be placed in one of the circuits. A predicate device shall be placed in the second test circuit. Priming and debubbling of the circuits by recirculating with an appropriate solution is recommended before blood is added. The blood pathway test-liquid volumes shall, at the initiation of the test, be within 1 % of each other. Perform the test in vitro using the conditions given in Table 1 . A sufficient number of paired tests should be performed to support a statistical analysis. The predicate oxygenator should be tested under the same conditions. The sampling schedule shall be in accordance with Table 2. More frequent sampling times are optional.

5.4.5.2 Procedure

Pass 500 ml of the test liquid at room temperature (20 °C to 22 °C) through the device at a flow rate of no less than 1 00 ml/min and a pressure not exceeding 1 52 kPa (22 psi) gauge. Determine the pre and post-filtration mean number of particles. The test shall be performed at the manufacturer’s recommended flow rates. Calculate the filtration efficiency, using the readings from the size range of the test particles used for each test sample, by subtracting the post-filtration mean number of particles from the pre-filtration mean, dividing the quotient by the pre-filtration mean number of particles, and multiplying by 100 to obtain a percentage.

5.4.7.2 Procedure

Use filter vent tubing as specified in the manufacturer’s instructions for use. The length and internal diameter of the vent tubing shall be specified. The back pressure at the maximum test flow shall be 26,6 kPa (3,9 psi) ± 5 %. Use a bubble eliminator to measure any air downstream of the integral filter accumulated over a period of 5 min from bolus injection. At flow rates of 33 %, 67 %, and 1 00 % of the specified maximum rated flow rate, a bolus of 30 ml of room air for adult oxygenators (for paediatric or infant oxygenators with a maximum flow rate of less than 500 ml/min the bolus shall be 2,5 ml and for maximum flow rates higher than 500 ml/min the bolus shall be increased by 2,5 ml for every 500 ml/min maximum flow rate; the maximum bolus shall be 10 ml) shall be injected as a single bolus. Indication of the air bolus injection point in the test circuit, rate of injection, and type of pump utilized to circulate test liquid should be provided in the test protocol.