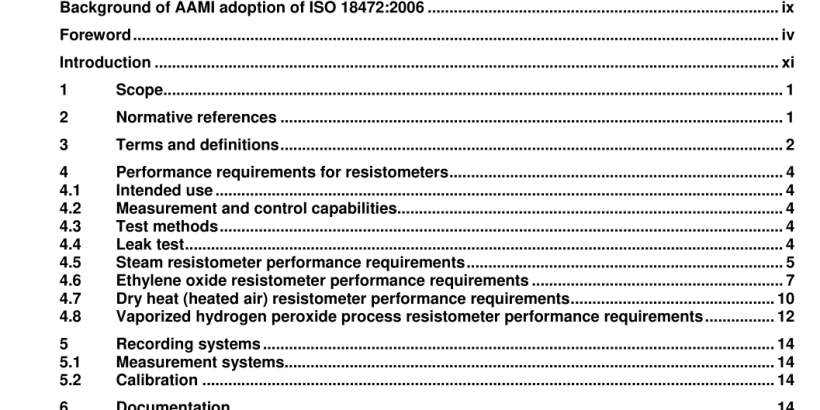

ANSI AAMI ISO 18472-2006 pdf download.Sterilization of health care products― Biological and chemical indicators― Test equipment

1 Scope

1.1 This International Standard specifies the requirements for test equipment to be used to test chemical and biological indicators for steam, ethylene oxide, dry heat and vaporized hydrogen peroxide processes for conformity to the requirements given in ISO 1 1 1 40-1 for chemical indicators, or the requirements given in the ISO 1 1 1 38 series for biological indicators. This International Standard also provides informative methods useful in characterizing the performance of biological and chemical indicators for intended use and for routine quality control testing. ISO 1 1 1 38-2, ISO 1 1 1 38-3, ISO 1 1 1 38-4, and ISO 1 1 1 40-1 require the use of resistometers specified in this International Standard, and these resistometers are used in conjunction with the test methods specified in the appropriate parts of ISO 1 1 1 38 and ISO 1 1 1 40. NOTE Resistometers for formaldehyde indicators are not included in this International Standard. Test methods using laboratory apparatus for steam-formaldehyde are included in ISO 1 1 1 38-5, ISO 1 1 1 40-3, and ISO 1 1 1 40-4.

1.2 This International Standard does not address the methods used to demonstrate compliance of biological or chemical indicators to ISO 1 1 1 38 and ISO 1 1 1 40, as these are covered in the appropriate parts of these standards. Indicators used with combination processes, such as washer-disinfection, are not covered by this International Standard. NOTE Test equipment and methods necessary for ISO 1 1 1 40-3, ISO 1 1 1 40-4 or ISO 1 1 1 40-5 are specified in those standards.

1.3 This International Standard does not address safety aspects of the test equipment because these are usually covered by specific regional, national or local regulations.

4.1 Intended use

The resistometer is intended to be used to expose test samples under stated test conditions, and therefore shall be capable of producing cycle sequences as required for specific test methods. Depending upon the test methods defined in ISO 1 1 1 38-2, ISO 1 1 1 38-3, ISO 1 1 1 38-4, and ISO 1 1 1 40-1 , the resistometer utilized need only verify those limits necessary to characterize the chemical or biological indicators. NOTE The following specifications define the conditions to be achieved in the vessel in which the sample is to be placed, but the means by which these conditions are to be controlled are not addressed.

4.4.1 With the temperature stabilized and the chamber empty (except for fixed furniture and necessary monitoring sensors) start the test cycle. When the pressure in the chamber has reached or is below the value corresponding to the lowest operating vacuum of the test cycle air removal stages, close all the valves connected to the chamber and stop the vacuum pump. Observe and record the time, t 1 , and the absolute pressure, p 1 . Allow evaporation of condensation in the chamber for 300 s ± 1 0 s and then observe and record the absolute pressure, p 2 , in the chamber and the time, t 2 . After a further 600 s ± 1 0 s, again observe and record the absolute pressure, p 3 , and the time, t 3 . The resistometer may be fitted with a test cycle for air leakage that will carry out this procedure automatically and display the air leakage in kPa/min (mbar/min).

4.4.2 At the end of the test calculate the rate of pressure rise for the 600 s period. NOTE 1 If the value of (p 2 − p 1 ) is greater than 2 kPa (20 mbar), this could be due to the initial presence of excessive condensate in the sterilizer chamber. NOTE 2 In a closed vessel at 4 kPa pressure, the pressure changes by approximately 0.1 kPa (1 mbar) for each 1 0 °C change in temperature; over the range 20 °C to 1 40 °C; at 7 kPa (70 mbar) the change is approximately 0.2 kPa (2 mbar). The test can be compromised if the temperature changes by more than 1 0 °C during the period in which the chamber pressure is monitored.ANSI AAMI ISO 18472-2006 pdf download