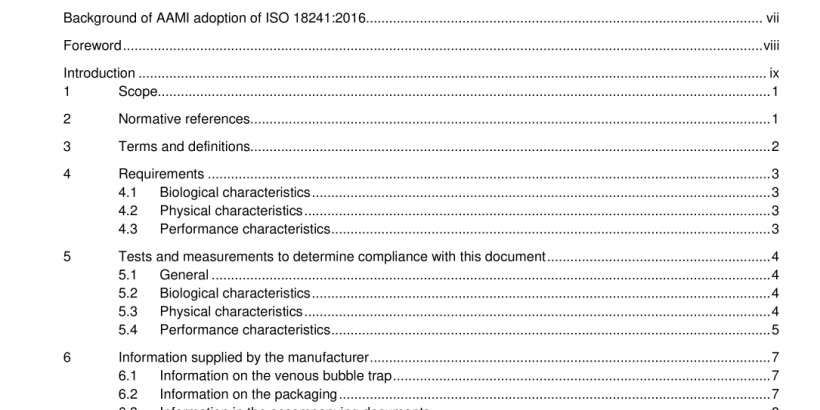

ANSI AAMI ISO 18241-2016 pdf download

ANSI AAMI ISO 18241-2016 pdf download.Cardiovascular implants and extracorporeal systems—Cardiopulmonary bypass systems— Venous bubble traps

1 Scope

This document specifies requirements for sterile, single-use, venous bubble traps intended to remove air entering the venous line during surgical procedures requiring extracorporeal circulatory support, which may include cardiopulmonary bypass (CPB), extracorporeal membrane oxygenation (ECMO), or venovenous bypass for liver transplantation.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 594-2, Conical fittings with 6 % (Luer) taper for syringes, needles and certain other medical equipment — Part 2:Lock fittings

ISO 1 0993-1 , Biological evaluation of medical devices — Part 1: Evaluation and testing within a risk management process

ISO 1 0993-4, Biological evaluation of medical devices — Part 4: Selection of tests for interaction with blood

ISO 1 0993-7, Biological evaluation of medical devices — Part 7: Ethylene oxide sterilization residuals

ISO 1 0993-1 1 , Biological evaluation of medical devices — Part 11: Tests for systemic toxicity

ISO 1 1 1 35-1 , Sterilization of health care products — Ethylene oxide — Part 1: Requirements for development,validation and routine control of a sterilization process for medical devices

ISO 1 1 1 37-1 , Sterilization of health care products — Radiation — Part 1: Requirements for development, validation and routine control of a sterilization process for medical devices

ISO 1 1 607-1 , Packaging for terminally sterilized medical devices — Part 1: Requirements for materials, sterile barrier systems and packaging systems

ISO 1 1 607-2, Packaging for terminally sterilized medical devices — Part 2: Validation requirements for forming,sealing and assembly processes

ISO 1 4937, Sterilization of health care products — General requirements for characterization of a sterilizing agent and the development, validation and routine control of a sterilization process for medical devices

ISO 1 7665-1 , Sterilization of health care products — Moist heat — Part 1: Requirements for the development,validation and routine control of a sterilization process for medical devices

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses.

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at http://www.electropedia.org/

5.4.1.1.2 Procedure

Two sets of appropriate, identical circuit components, including a pump, connecting tubing, a reservoir (as specified by the manufacturer and of suitable size relative to the device under test), and a means of controlling temperature, shall be assembled. The device under test shall be placed in one of the circuits between the inflow of a blood pump and the outlet of a patient simulating reservoir per the manufacturer’s instructions for use. A predicate device shall be placed in the second test circuit. Priming and debubbling of the circuits by recirculating with an appropriate solution is recommended before blood is added. The blood pathway test liquid volumes shall, at the initiation of the test, be within 1 % of each other. Perform the test in vitro using the conditions given in Table 1 . If the instructions for use call for connection to ancillary devices, these should be connected and operated at the worst case conditions allowed per the manufacturer’s instructions for use. A sufficient number of paired tests should be performed to support a statistical analysis. The predicate venous bubble trap should be tested under the same conditions. Compliance shall be verified by test or by inspection of the manufacturer’s documentation on blood cell damage for the finished device, in accordance with ISO 1 0993-4, as applicable.