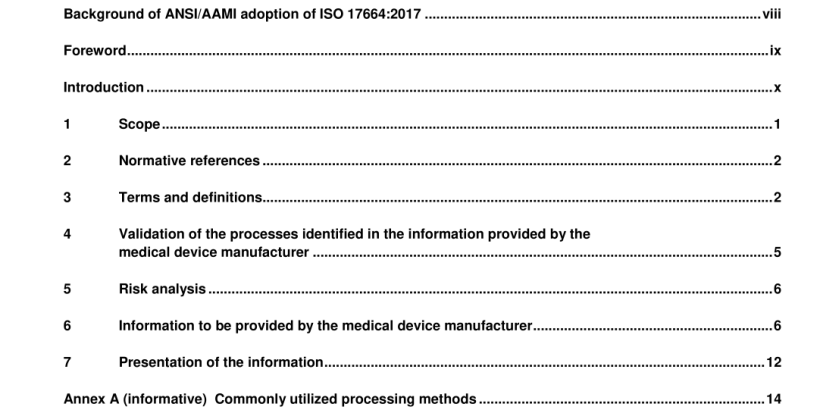

ANSI AAMI ISO 17664-2017 pdf download

ANSI AAMI ISO 17664-2017 pdf download.Processing of health care products—Information to be provided by the medical device manufacturer for the processing of medical devices

4 Validation of the processes identified in the information provided by the medical device manufacturer

4.1 The medical device manufacturer shall validate each process that is identified in the information supplied with the medical device. Validation shall demonstrate that each process is suitable for processing of the medical device.

4.2 The medical device manufacturer shall have objective evidence available that validation of the processing procedures has been undertaken to confirm that the specific medical device will be clean, disinfected and/or sterilized when processed as directed. NOTE 1 In addition to the duty of a manufacturer to demonstrate the validity of provided information, national authorities can require the final effectiveness of the process to be verified by the processor. NOTE 2 National authorities can allow or require the use of an alternative process. In such cases they usually require validation of those processes by the processor.

4.3 If a manufacturer supplies a number of different medical devices that share common attributes, then validation studies may be performed as a product family. If this approach is taken, the medical device manufacturer shall demonstrate commonality between the different medical devices and the validation studies shall address the worst case attribute(s) of the product family.

6.1 6.1.1 The information specified in this clause shall take into account the nature of the medical device and its intended use.

6.1.2 Where disinfection is the terminal process, the medical device manufacturer shall specify validated method(s) to reduce the risk of transmission of infectious agents to a level appropriate for the intended use of the medical device. Medical device manufacturers shall specify in their processing instructions any special techniques and accessories that will enable the processor to provide a medical device that is suitable for its intended use.

6.1.3 Where sterilization is the terminal process, the medical device manufacturer shall specify validated method(s) to achieve the required sterility assurance level. Medical device manufacturers shall specify in their processing instructions any specific requirements that will enable the processor to provide a medical device that is suitable for its intended use.

6.6.1.1 At least one validated automated cleaning method (which may include a validated manual cleaning method as part of the automated cleaning validation) shall be specified unless the medical device cannot withstand any such process, in which case a statement shall be provided which alerts the user to this issue.

6.6.1.2 A validated method of manual cleaning shall be specified if automated cleaning is not possible.

6.6.2 Automated cleaning

6.6.2.1 If the automated cleaning process recommends the use of a washer-disinfector meeting the requirements of the ISO 1 5883 series, the information regarding the automated process may be limited to those parameters that are specific for the medical device, such as specific load configuration, positioning, connection, accessories, process chemicals, pressures or temperature limit(s) and a statement confirming the recommendation to use a washer-disinfector complying with the ISO 1 5883 series.

6.7.2.1 If the automated disinfection process recommends the use of a washer-disinfector meeting the requirements of the ISO 1 5883 series, the information regarding the automated process may be limited to those parameters that are specific for the medical device, such as specific load configuration, positioning, connection, accessories, chemical (in the case of chemical or chemo-thermal disinfection), pressures or temperature limit(s) and a statement confirming the recommendation to use a washer-disinfector complying with the ISO 1 5883 series.