ANSI AAMI ISO 15676-2016 pdf download

ANSI AAMI ISO 15676-2016 pdf download.Cardiovascular implants and artificial organs— Requirements for single-use tubing packs for cardiopulmonary bypass and extracorporeal membrane oxygenation (ECMO)

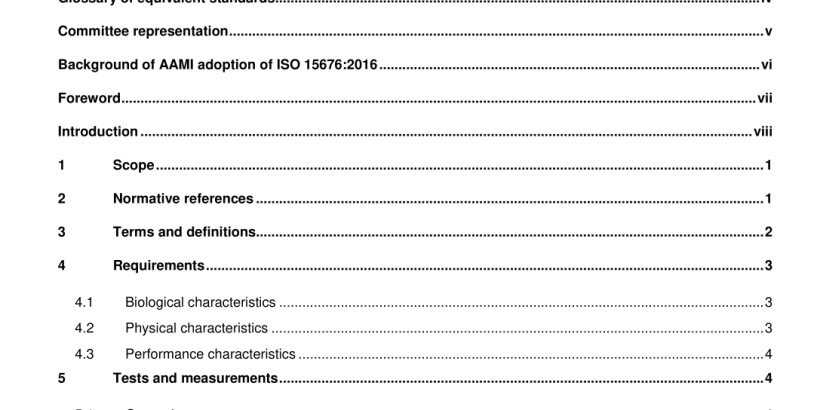

1 Scope

This document specifies requirements for single-use tubing packs for cardiopulmonary bypass and extracorporeal membrane oxygenation (ECMO). This document is applicable to all medical tubing intended for cardiopulmonary bypass (CPB) and/or extracorporeal membrane oxygenation (ECMO), but specific requirements and tests are included for tubing intended for use with peristaltic pumps during (short-term, i.e. <6 h duration) CPB surgery or (long- term, i.e. >24 h) ECMO procedures. The sterility and non-pyrogenicity provisions of this document are applicable to tubing packs labelled as “sterile”. This document is applicable only to the tubing aspects for multifunctional systems that may have integral components such as blood gas exchangers (oxygenators), reservoirs, blood filters, defoamers, blood pumps, etc.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 34-1 , Rubber, vulcanized or thermoplastic — Determination of tear strength — Part 1: Trouser, angle and crescent test pieces

ISO 527-1 , Plastics — Determination of tensile properties — Part 1: General principles

ISO 9352, Plastics — Determination of resistance to wear by abrasive wheels

ISO 1 0993-1 , Biological evaluation of medical devices — Part 1: Evaluation and testing within a risk management process

ISO 1 0993-7, Biological evaluation of medical devices — Part 7: Ethylene oxide sterilization residuals

ISO 1 0993-1 1 , Biological evaluation of medical devices — Part 11: Tests for systemic toxicity

ISO 1 7665-1 , Sterilization of health care products — Moist heat — Part 1: Requirements for the development,validation and routine control of a sterilization process for medical devices

ISO 1 1 1 35, Sterilization of health-care products — Ethylene oxide — Requirements for the development, validation and routine control of a sterilization process for medical devices

ISO 1 1 1 37-1 , Sterilization of health care products — Radiation — Part 1: Requirements for development, validation and routine control of a sterilization process for medical devices

ISO 1 1 1 37-2, Sterilization of health care products — Radiation — Part 2: Establishing the sterilization dose

ISO 1 1 607-1 , Packaging for terminally sterilized medical devices — Part 1: Requirements for materials, sterile barrier systems and packaging systems

ISO 1 1 607-2, Packaging for terminally sterilized medical devices — Part 2: Validation requirements for forming,sealing and assembly processes

ISO 1 4937, Sterilization of health care products — General requirements for characterization of a sterilizing agent and the development, validation and routine control of a sterilization process for medical devices

ASTM D792-00, Standard test methods for density and specific gravity (relatively density) of plastics by displacement

ASTM D2240-04, Standard test method for rubber property — Durometer hardness

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1 durometer hardness

measure of hardness of elastic materials by Shore A range

3.2 elongation

increase in linear dimension

3.3 tensile strength

force per unit of original cross section on elongation (3.2) to rupture

3.4 tear strength

measure of stress needed to continue rupturing a sheet of rubber or plastic, usually after an initial cut

5.3.1.1 The test shall be performed at 37 °C with air or water at the appropriate pressures.The test shall be performed to ensure freedom from leaking.

5.3.1.2 Subject the tubing to a positive pressure of 1 ,5 times the manufacturer’s rated pressure or, if no maximum pressure is specified, the test shall be performed at 1 52 kPa for 6 h or as long as it is specified by the manufacturer for clinical use. Using air pressure decay or visual inspection, check for leakage.

5.3.2 Connections

The connections shall withstand a pull force of 1 5 N for 1 5 s without separating. Testing shall be performed as specified in the manufacturer’s protocol.

5.3.3 Tubing material property testing Tubing material property testing shall be determined in accordance with the requirements of ISO 34-1 , ISO 527-1 , ISO 9352, ASTM D792-00, and ASTM D2240-04, as applicable or consistent with the requirements of the end user.