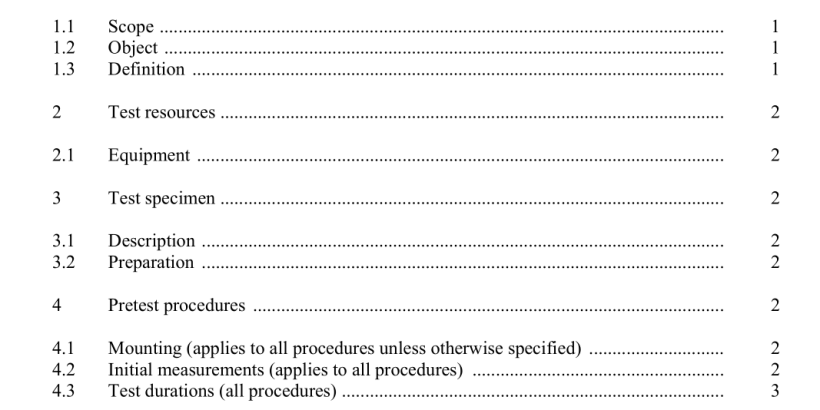

ANSI EIA 364-31E-2017 pdf download.Humidity Test Procedure for Electrical Connectors and Sockets

2.1 Equipment

The test chamber and accessories shall be constructed and arranged in such a manner as to avoid condensate dripping on the test specimen. A suitable open screen tray or rack shall be provided to ensure that the specimen shall be exposed to circulating air. Specimens shall not be subjected to radiant heat from chamber conditioning processes. The chamber shall be trap-vented to the atmosphere to prevent the buildup of total pressure. When readout charts are used, they shall be capable of being read with a resolution within 0.6 °C (1 °F). The relative humidity shall be controlled within ± 3%, and the temperature within ± 3 ºC (± 5 ºF). Steam, distilled, demineralized, or deionized water shall be used to obtain the specified humidity. No rust or corrosion contaminants shall be imposed on the test specimen by the test facility.

3.1 Description: A test specimen shall consist of individual plugs, receptacles, or mated assemblies including accessories, shells, heat sinks, etc. that are normally part of the assembly.

3.2 Preparation: The specimens, when specified, shall be wired using the contacts, wire type, size and, if applicable, sealing plugs. When required, and as applicable, mounting to test boards shall be indicated. Moisture absorption and temperature ratings should be reviewed when selecting test board material. Conformal coating may be used.

4 Pretest procedures

4.1 Mounting (applies to all procedures unless otherwise specified)

The specimens shall be placed in the test chamber in their normal application orientation, unless otherwise specified. They shall be so positioned that they do not contact each other and shall be minimum of 5 centimeters (2 inches) from each other and any chamber surface. There shall be no drip loops in wires.

4.2 Initial measurements (applies to all procedures)

Unless otherwise specified, prior to any initial preconditioning, the pre exposure measurements as specified shall be performed at room ambient conditions.

5.1.1 Test start

Unless otherwise specified in the referencing document, the specimens shall be placed in the chamber at room ambient conditions. The chamber shall then be ramped to the initial test conditions, and the exposure shall proceed as specified in the referencing document.

5.1.2 Removal and recovery

If specified in the referencing document, removal and recovery of test specimens shall proceed upon completion of exposure in accordance with the reference document. Otherwise, the specimens shall return to ambient conditions. Test specimens shall not be subjected to any means of artificial drying. If condensation is observed on the specimens, test sponsor shall be notified.

5.1.3 Final measurements

Final measurements shall be performed in accordance with the reference document before, during, or after recovery, if so specified. Unless otherwise specified in the referencing document, final measurements shall be performed after return of test specimens to ambient conditions following completion of exposure. If the referencing document or measurement procedure specifies measurements to be conducted after a recovery period, but does not specify the duration of the recovery period, the recovery period shall be 24 hours at ambient conditions. Specimens shall not be subjected to any means of artificial drying.

Method III has been discontinued and superseded by Method IV. However in legacy applications that specified Method III, step 7b; step 7b shall be performed following step 7a in Method IV. Step 7b consisted of subjecting the specimens (within 15 minutes after completion of step 7a, when specified in the referencing document, and with humidity not controlled) to vibration for 15 minutes, at room ambient temperature; using a simple harmonic motion of 0.15 millimeter (0.006 inch) maximum total excursion, the frequency being varied uniformly between the approximate limits of 10 and 55 Hz. The entire frequency range, from 10 to 55 Hz and return to 10 Hz, shall be traversed in approximately one minute.ANSI EIA 364-31E-2017 pdf download