ANSI Z80.10-2018 pdf download.Ophthalmic Instruments – Tonometers

1 Scope

This standard, together with ISO 1 5004-1 :2006, Fundamental requirements and test methods – Part 1: General requirements applicable to all instruments – First edition, specifies minimum requirements and the design compliance procedure for tonometers intended for routine clinical use in the estimation of intraocular pressure (IOP) for the detection, diagnosis, and management of ocular abnormalities. NOTES 1 ) The true intraocular pressure is seldom directly measured since it would require invasion of the eye. Since the true IOP cannot be known, the instrument (annex A) and method (annex B) for determining a reference IOP are established. 2) Clinical tonometers may employ different parameters or correlates in the indirect assessment of measured IOP. The manufacturer states the exact design parameters of the specific tonometer, and then, on the basis of design compliance testing as specified in 4.2, demonstrates that the specific design performs acceptably compared to the reference method. This process is referred to as certification. The manufacturer also demonstrates, by methods specified in 4.3, that individual manufactured instruments perform the same as (within defined limits) the test tonometer. This process is referred to as verification.

2 Normative references

The following standards contain provisions which, through reference in this text, constitute provisions of this Standard. At the time of publication, the editions indicated were valid. All standards are subject to revision, and parties to agreements based on this standard are encouraged to investigate the possibility of applying the most recent editions of the standards listed below. Members of IEC and ISO maintain registers of currently valid standards.

4.1 General

The tonometer shall conform to the requirements specified in ISO 1 5004:1:2006. The tonometer shall conform to the specific requirements specified in 4.2 to 4.4 for measured values designated as Goldmann-equivalent. This standard does not prevent presentation of additional parameters or interpretations of the data that differ from Goldmann-equivalent measurements. However, if compliance with this standard is claimed, a tonometer shall make Goldmann-equivalent values available to the user and shall designate them as measurements conforming to ANSI Z80.1 0.

4.2 Type testing (certification)

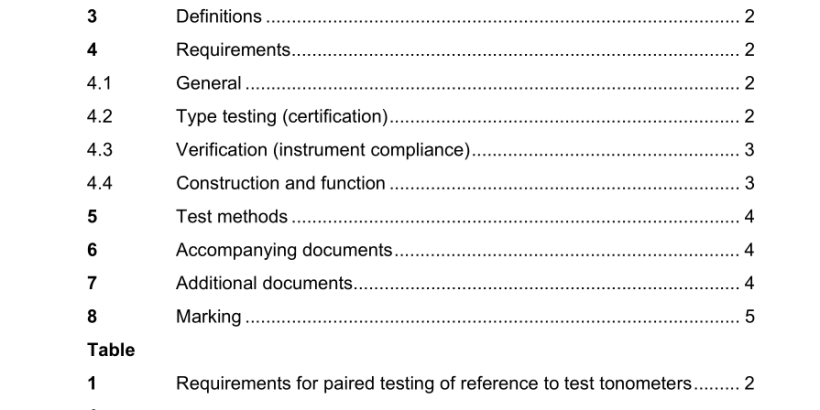

4.2.1 The manufacturer shall demonstrate, on the basis of design compliance testing as specified in clause 5, that the test tonometer measurements compared to the reference tonometer measurements meet the requirement as given in table 1 .

The requirements are met if not more than 5% of the paired differences between the reference tonometer reading and the test tonometer reading for each pressure range are greater than the tolerance for that range in table 1. NOTE – The tolerances given in table 1 represent 1 .96 times the standard deviation allowable for the paired measurement and so account for not only the allowable error of the tonometer under test but also the unavoidable error associated with the reference tonometer. Individual variability may be lower.

4.2.2 The manufacturer shall analyze the data, taken in the course of design compliance testing, as specified in clause 5, using the method of Total Least Squares Regression, and make available, as required in part (a) of clause 7, the slope of the regression, the offset of the regression and the standard deviation of the regression.

4.3.1 The manufacturer shall develop a method and test apparatus to confirm that the requirements of 4.2 are met by each manufactured tonometer. Each tonometer shall be verified with this method and apparatus. This method and test apparatus shall be the same that were used to measure and verify the test tonometer in 4.2. Details of the method and test apparatus shall be made available in accordance with the requirements of clause 7.ANSI Z80.10-2018 pdf download