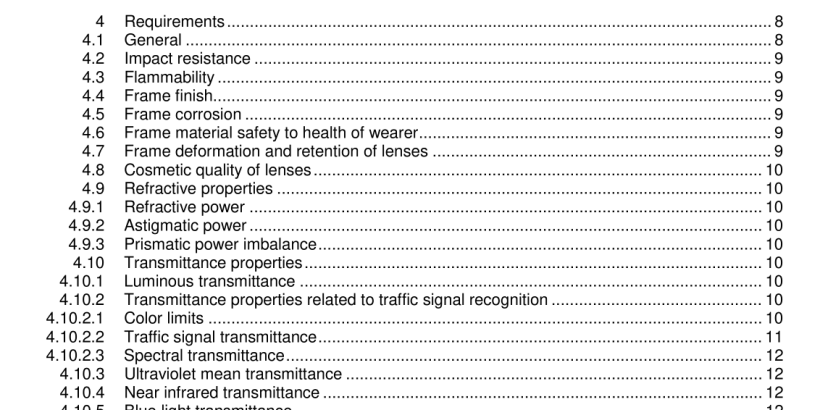

ANSI Z80.3-2018 pdf download.Nonprescription Sunglass and Fashion Eyewear Requirements

1.1 Scope

This standard applies to all nonprescription sunglasses and fashion eyewear, normally used for casual, dress, and recreational purposes, having lenses of substantially plano power. This standard specifically excludes products covered by ANSI Z87.1 , ANSI Z80.1, and those covered within the ASTM F08.57 committee. Sunglass needs for aphakics may not be met by this standard.

1.2 Purpose

The purpose of this standard is to establish standards for noncorrective (essentially plano power) lenses that are intended for attenuation of light and for fashion eyewear, and for the flammability and durability of frames and lenses. These products are commonly called sunglasses, and they are not designed to be industrial safety eyewear as defined in ANSI Z87.1 , or to provide corrective prescriptions as defined in ANSI Z80.1 , or to provide protection for selected sports as defined within ASTM F08.57 committee standards, or to provide protection when making direct observation of the sun, such as for viewing a partial or annular solar eclipse. Lenses covered by this standard are not intended for use under conditions of reduced illumination; however, variable tint lenses that fade to a luminous transmittance greater than 75% are covered. Lenses with less than 75% luminous transmittance anywhere on the lenses are not suitable for driving under low light conditions, such as but not limited to twilight or night.

4.3 Flammability

Flammability testing shall be performed in accordance with the procedures specified in 5.3. Compliance with flammability requirements shall be determined by the manufacturer for each type of material when first used, or when change is made in any coatings used on the material. This applies to plastic frames, plastic lenses, or the assembled product.

4.4 Frame finish

The surface finish of metal and plastic frames shall be free of significant imperfections or roughness. All hardware or other components shall be free of burrs or hazardous projections. Excessive polishing compounds or other processing residue shall not be present. The surface finish of plastic frames shall be free of significant imperfections or roughness. All hardware or other metal components shall be free of burrs, and all exposed metal parts shall be corrosion resistant as defined in 4.5.

4.5 Frame corrosion

Metal frames shall be manufactured of materials that of themselves provide corrosion resistance for their intended functional and cosmetic purposes under usual environmental conditions. Other materials may be used, provided they are surface coated with one or more layers of coating that provide corrosion resistance. Corrosion resistance of metal parts shall be sufficient to pass the test method described in 5.4. Frames with movable hinges shall move as designed after being subjected to test conditions.

4.6 Frame material safety to health of wearer

Sunglasses shall be designed and manufactured in such a way that when used under the conditions and for the purposes intended, they will not compromise the health and safety of the wearer. The risks posed by substances, such as nickel, leaking from the device that may come into prolonged contact with the skin shall be reduced by the manufacturer to below any regulatory limit. Special attention shall be given to substances that are allergenic, carcinogenic, mutagenic, or toxic to reproduction.

NOTE – Reactions may be generated by excessive pressure due to a poor fit on the face, chemical irritation, or allergy. Rare or idiosyncratic reactions may occur to any material and may indicate the need for the individual to avoid particular materials.ANSI Z80.3-2018 pdf download