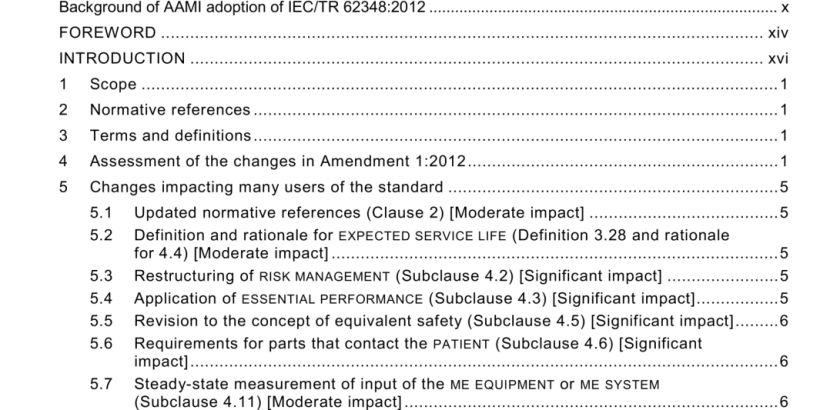

ANSI AAMI IEC TIR62348-2012 pdf download

ANSI AAMI IEC TIR62348-2012 pdf download.Assessment of the impact of the most significant changes in Amendment 1 to IEC 60601-1 :2005 and mapping of the clauses of IEC 60601-1:2005 to the previous edition

5.3 Restructuring of RISK MANAGEMENT (Subclause 4.2) [Significant impact]

Subclause 4.2 and its rationale have been significantly modified and expanded. The subclause describes in greater detail the RISK MANAGEMENT PROCESS to be employed in complying with IEC 60601-1. Subclause 4.2. 1 introduces the concepts and the purposes of RISK MANAGEMENT within the framework of a TYPE TEST or design assurance standard. The subclause includes a reminder that, “verification of compliance with the RISK MANAGEMENT requirements of this standard can be accomplished by examination of the RECORDS and other documentation required by this standard and assessment of the processes cited in this standard and does not require auditing of the RISK MANAGEMENT PROCESS.” Subclause 4.2.2 is the heart of the subclause and sets out the basic PROCESS requirements, which remain in compliance with ISO 14971 except for the requirements related to product and post- production monitoring and periodic reviews of the suitability of the RISK MANAGEMENT PROCESS. Subclause 4.2.3 details how the requirements of this standard are to be applied when evaluating RISK. There are four scenarios described. They are:

a) where IEC 60601-1 or its collateral or particular standards specify requirements addressing particular HAZARDS or HAZARDOUS SITUATIONS, together with specific acceptance criteria;

b) where IEC 60601-1 or its collateral or particular standards specify requirements addressing particular HAZARDS or HAZARDOUS SITUATIONS but do not provide specific acceptance criteria;

c) where IEC 60601-1 or its collateral or particular standards identify particular HAZARDS or HAZARDOUS SITUATIONS that have to be investigated without providing specific technical requirements; and

d) where HAZARDS or HAZARDOUS SITUATIONS are identified for the particular ME EQUIPMENT or ME SYSTEM but are not specifically addressed in this IEC 60601-1 or its collateral or particular standards.

Subclause 4.3 has been revised and extended to discuss the process the MANUF ACTURER can use to determine the ESSENTIAL PERFORMANCE of ME EQUIPMENT or an ME SYSTEM. The fundamental goal was not to change the intent of the concept but make it easier to understand and apply. The definition and the process in 4.3 have been changed to focus on clinical functions and to try an exclude “performance” related to BASIC SAFETY, e.g., the performance of insulation. However,remember, regardless of whether we are speaking of BASIC SAFETY or ESSENTIAL PERFORMANCE, both must be managed. The rationale for Subclause 4.3 has also been updated. .

5.5 Revision to the concept of equivalent safety (Subclause 4.5) [Significant impact]

Recognizing that demonstrating “equivalent safety” can be difficult because many of the requirements in IEC 60601-1 do not provide sufficient detail regarding the level of RESIDUAL RISK, this subclause has been modified to allow alternative RISK CONTROL measures or test methods when it can be demonstrated that that the RESIDUAL RISK resulting from application of the alternative RISK CONTROL measure or test method remains acceptable and is comparable to the RESIDUAL RISK that results from applying the requirements of this standard. The RESIDUAL RISK must satisfy the MANUFACTURER’S RISK acceptance criteria and must be comparable to that remaining after applying the requirements of the standard. The MANUFACTURER can demonstrate this by applying:

– scientific data,

– clinical opinion,

– comparative studies, or

– a combination of all three methods.

5.8 Simultaneous fault testing (Subclause 5. 1) [Moderate impact]

Subclause 5.1 was modified to clarify the requirement that the combination of simultaneous independent faults that could result in a HAZARDOUS SITUATION be documented in the RISK MANAGEMENT FILE. The original text of IEC 60601-1:2005 required that the results of the RISK ANALYSIS be used to determine which combination(s) of simultaneous faults were to be tested. Since the RISK ANALYSIS is documented in the RISK MANAGEMENT FILE, this is not a new requirement. When testing is necessary to demonstrate that BASIC SAFETY and ESSENTIAL PERFORMANCE are maintained under such simultaneous independent faults, the related testing may be limited to worst case situations. Because of the potential for additional documentation, this was judged to be of moderate impact.