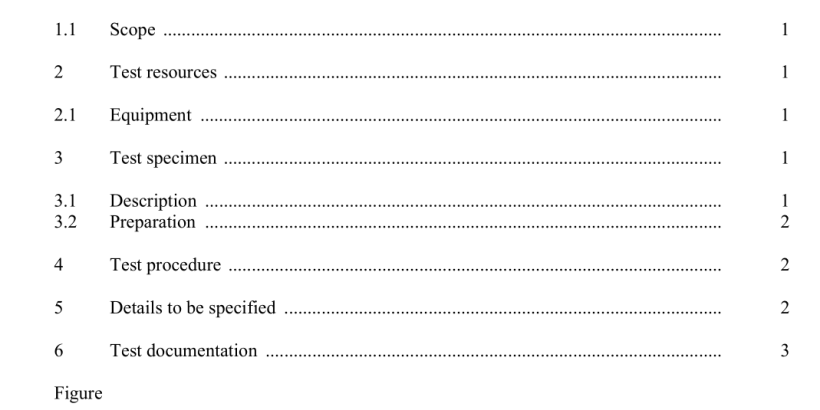

ANSI EIA 364-25E-2017 pdf download.Probe Damage Test Procedure for Electrical Connectors

1.1 Scope

This standard establishes a test method to be followed for probe damage testing; intended primarily for round socket contacts in electrical connectors and possibly applicable to other type contacts as well. This test is to simulate a form of field abuse of contacts during test by inserting probes into socket contacts. The purpose of this test is as follows:

– to simulate probing of socket contacts while installed in the connector for non-removable contacts and for removable contacts while outside of the connector housing;

– to verify performance characteristics of the socket contacts have not been adversely impacted as may be specified in the referencing document (i.e. engagement and separation forces).

2.1 Equipment

The equipment required to perform the test shall be a probe damage tool similar to that shown in figure 1 and mounting fixtures similar to that shown in figures 2 and 3. The test pin shall be as shown in figure 1 and shall be of hardened steel or tungsten carbide and have a polished surface containing a 0.15 micrometer (6 microinches) to 0.25 micrometer (10 microinches) finish.

3.2 Preparation

3.2.1 Crimp or other removable contacts shall use a suitable collet type holding device, as shown in figure 2, unless otherwise specified in the referencing document. Non-removable socket contacts shall be tested in their connector housing, as shown in figure 3.

3.2.2 The collet type holding device shall not support the contact in any way that interferes with the free rotation of the test probe fixture. The collet device shall grip the contact on the contact crimp barrel, or the termination end of the contact (e.g. wrap-type terminations, solder-tail, compliant pin, etc.) with the contact shoulder flush against the collet device. The collet shall not interfere with the socket spring member under test.

4 Test procedure

4.1 The connector or the collet device with the socket contacts fixed in place shall be mounted in a horizontal position to a rotating fixture to allow 360° hand rotation during test; see figures 2 and 3.

4.2 The probe damage tool, see figure 1, shall be inserted into the contact to a “B” dimension depth as illustrated in figure 1. The “B” dimension shall be both 1/2 and 3/4 of socket bore minimum depth specified in the referencing document. The amount the socket contact is recessed from the front of the housing shall be added to probe length “B” when a connector holding device is used. Unless otherwise specified in the referencing document the tolerance on the “B” dimension shall be minus 0 millimeter (0 inch) plus 0.127 millimeter (0.005 inch).

4.3 When the test setup is in conformance with 4.1 and 4.2 the fixture shall be slowly rotated once through 360° at a uniform rate of no less than a 5 second rotation and no more than a 15 second rotation, unless otherwise specified in the referencing document, with the probe damage tool inserted in the contact so that the force is applied uniformly to the inside diameter of the socket. The test shall be repeated so that both insertion depths (i.e., 1/2 and 3/4) are tested.

5 Details to be specified

The following details shall be specified in the referencing document:

5.1 Initial and final examination or measurement

5.2 Mounting of specimen, see clause 4. The collet device shall be defined in the referencing

document

5.3 Number and size of samples to be tested

5.4 Probe depth dimension

5.5 Number of 360° rotations indicated in 4.3 if other than one.ANSI EIA 364-25E-2017 pdf download