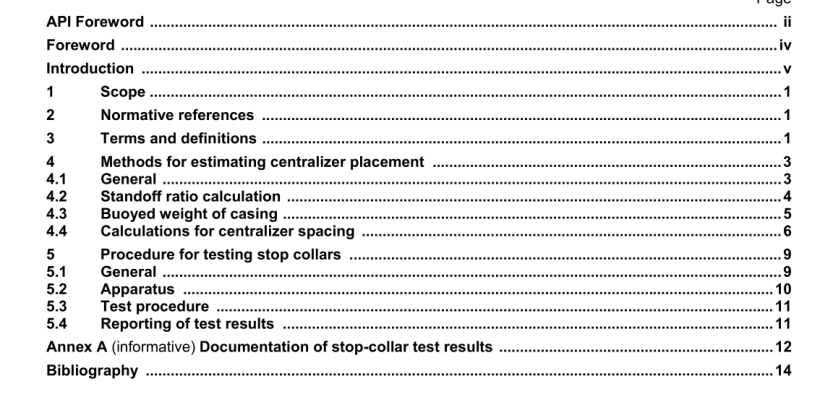

ANSI API RP 10D-2-2004 pdf download.Petroleum and natural gas industries — Equipment for well cementing

4.1 General

The equations presented below are based on certain assumptions and are considered sufficiently accurate for general use. More specific calculations based on complete wellbore data may be available but are beyond the scope of this document. There is no recommendation or requirement for a specific standoff ratio for casing centralization. The standoff ratio of 67 % is used in the specification for the purpose of setting a minimum standard for performance of casing bow-spring centralizers only. This number is used only in the specifications for bow-spring type centralizers and deals with the minimum force for each size of centralizer at that standoff. The 67 % standoff ratio is not intended to represent the minimum acceptable amount of standoff required to obtain successful centralization of the casing. The user is encouraged to apply the standoff ratio required for specific well conditions based on well requirements and sound engineering judgement. Even a minor change in inclination and/or azimuth, with the string of casing hanging below it, materially affects the standoff and the requirements for centralizer placement.

4.3.3 Discussion

The buoyed weight of the casing being cemented changes during a cementing operation. As the densities of the fluids inside the casing and the annulus change, the relative buoyed weight tends to reach a maximum when the highest density fluid is inside the casing, and a minimum when the highest density fluid is in the annulus. In the calculation of buoyed weight for centralizer spacing, the densities of the fluids both inside the casing and in the annulus should be considered. The calculated centralizer spacing can vary depending on the selection of fluid densities present during the cement job. The standoff ratio will change as the fluid densities change, and the user should note at what point during the cement job the required centralization standoff ratio needs to be met, and the appropriate buoyed weight for use in the calculations.

4.4 Calculations for centralizer spacing

4.4.1 General

The equations are valid only for casing strings with axial tension and do not apply for casing strings under compression. The equations do not consider end effects, for example at the shoe, the wellhead, or the liner hanger. The equations are valid only for calculating the casing deflection between two identical centralizers. The lateral load calculations are based upon a “soft string model” and do not take into effect casing stiffness. Additional models have been developed that consider the effects of compression on the casing standoff and lateral loads [4] .

5.1 General

For the purposes of this procedure, the term “stop collar” is used to indicate any type of device employed to prevent or limit movement of a centralizer on the casing. This includes stop collars that are independent of the centralizer and holding devices that are built into the centralizer, as in the case of solid or rigid centralizers. In this clause, the principles described for centralizers apply to other casing hardware that incorporate the use of a stop collar. Examples of these include cement baskets, scratchers, etc. The holding device used to prevent the slippage of a centralizer can be an independent piece of equipment, as in the case of a stop collar, or can be integral within the centralizer itself. Several types are available that include the use of screws, nails and mechanical dogs. Some manufacturers also recommend the use of resins in conjunction with their particular holding device. Regardless of the mechanism used to hold the centralizer in place, the holding device shall be capable of preventing slippage. While the holding force of the stop collar should be greater than the starting force of the centralizer, some multiplier should be applied depending on the particular well conditions. In the case of either solid or rigid centralizers, it is recognized that these types of centralizer do not have a starting force, as they have a constant outside diameter. The minimum holding force applied to these centralizers should follow the same guidelines as a bow-type centralizer that would be used in the same hole configuration. This same recommendation also applies to other casing hardware incorporating a stop collar.ANSI API RP 10D-2-2004 pdf download