ANSI AAMI ST21-1999 pdf download

ANSI AAMI ST21-1999 pdf download.Sterilization of health care products – Biological indicators

Following completion of the ISO 11138 series, the AAMI Biological Indicators Working Group, in the interests of international harmonization, agreed to consider adoption of the International Standards as replacements for two existing American National Standards- -ANSI/AAMI ST19:1986, Biological indicators for saturated steam sterilization processes in health care facilities, and ANSI/AAMI ST21:1 986, Biological indicators for ethylene oxide sterilization processes in health care facilities. These earlier documents had been developed by the AAMI Biological Indicators Working Group under the auspices of the AAMI Sterilization Standards Committee. They were originally published in 1986 and had been reaffirmed in early 1994, pending completion of the ISO 11138 series. In 1995, a canvas of the AAMI Sterilization Standards Committee and the AAMI Biological Indicators Working Group was undertaken. Members of the committee and the working group were asked whether the ISO standards should be considered for adoption as American National Standards without change, or should be modified for U.S. adoption, or whether the U.S. should continue to maintain ANSI/AAMI ST19 and ANSI/AAMI ST21 as domestic standards. Based on the results of the canvas and the discussion at the meeting, the AAMI Biological Indicators Working Group agreed that several modifications were required before the ISO 11138 series would be acceptable as American National Standards. These modifications were considered necessary given traditions of use of BIs in the U.S., and were consistent with positions advocated by the U.S. during the development of the ISO standards.

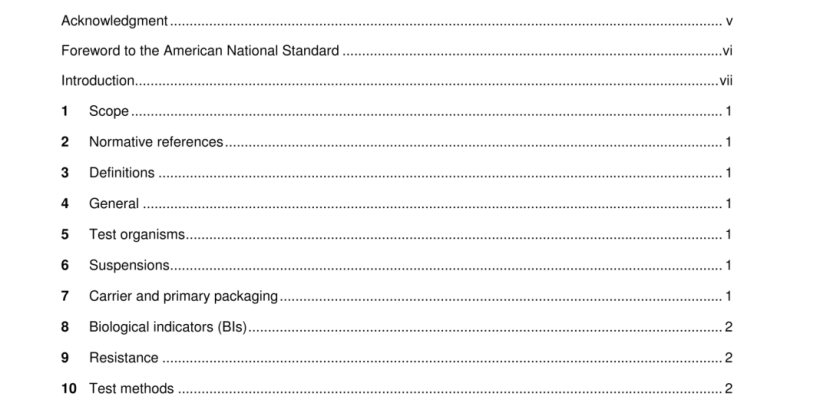

8 Biological indicators (BIs)

8.1 The number of recoverable test organisms on each BI shall be controlled during manufacture to be either within t 50% of the nominal population stated by the manufacturer or within the minimum and maximum populations stated by the manufacturer.

8.2 Retrospective determination of the count shall be made by performing a viable test organism count under the manufacturer’s stated culture conditions on a suspension of test organisms obtained by physical removal of the test organisms from the carrier through ultrasonication, shaking with glass beads, or other appropriate validated methods. Counts obtained shall be regarded as acceptable if they are within一50% and + 300% of the stated value or, if minimum and maximum populations are stated by the manufacturer, within those stated minimum and maximum populations.

8.3 For inoculated carriers and BIs intended for use in routine monitoring, the nominal population shall not be less than1 X 10° stated in increments no greater than0.1 x 10°. NOTE -Inoculated carriers and BIs intended for other purposes (e.g, qualification, validation, or other specific tests) could require other nominal populations. Other inoculum levels may be uilized for routine monitoring of industrial ethylene oxide processes, provided that level has been shown to be appropriate during process qualification.

Rationale: ISO 11138-2 provides minimum performance requirements for resistometers used to evaluate ethylene oxide sterilization BIs, which conflicted with the requirement given in the existing American National Standard for such resistometers. When a system is being evacuated, the temperature of the system changes considerably. A vacuum level cannot be pulled to a set point within this tight tolerance as the temperature changes will alter the consistency of the actual vacuum level obtained. The tolerance given is so tight (+0.4 kPa) that it approaches the feasible measurement level of precision pressure instrumentation, much less achievable control levels. At the rate of vacuum change prescribed, a control system cannot measure the pressure and stop the evacuation within such a tight tolerance.