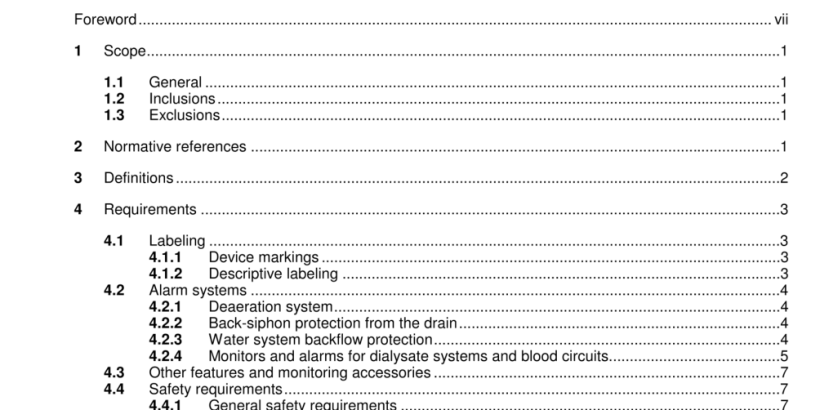

ANSI AAMI RD5-2003 pdf download

ANSI AAMI RD5-2003 pdf download.Hemodialysis equipment

1.2 Inclusions

This standard covers apparatus for preparing dialysate; monitors of the dialysate including blood leak detectors, ultrafiltration monitors, and controllers; integral blood pumps and heparin infusion pumps; and extracorporeal blood circuit monitors such as air detectors and pressure and flow monitors that are customarily supplied as a single comprehensive system. Some systems include monitors of patient blood pressure, blood volume, and online clearance, and others have the capability for computer interface with automated data systems. Where applicable, the monitoring for hemodiafiltration, hemofiltration, and home hemodialysis systems are also included. The requirements established by this standard will, at a minimum, help ensure the effective, safe performance of hemodialysis systems, devices, and related materials.

1.3 Exclusions

Excluded from the scope of this standard are sorbent dialysate regeneration systems that regenerate and recirculate small volumes of dialysate (although their monitors should meet this standard); peritoneal dialysis systems; central delivery systems; water treatment systems; concentrates and concentrate preparation and distribution systems; hemodialyzers; blood tubing; individual infusion pumps; and blood access devices. Some of these devices, such as hemodialyzers and blood tubing, along with water treatment equipment and concentrates, are addressed in other American National Standards. NOTE- For an explanation of the need for this standard and the rationale for its specific provisions, see annex A.

2 Normative references

The following standards contain provisions that, through reference in this text, constitute provisions of this standard. At the time of publication, the editions indicated were valid. All standards are subject to revision, and parties to agreements based on this standard are encouraged to investigate the possibility of applying the most recent editions of the standards indicated below. The Association for the Advancement of Medical Instrumentation (AAMI) maintains a register of currently valid AAMI/American National Standards.

3.5 dialysate: Aqueous fluid containing electrolytes and usually dextrose, which is intended to exchange solutes with blood during hemodialysis. The word“dialysate” is used throughout this document to mean the fluid made from water (see normative reference 2.4) and concentrate(s) that is delivered to the dialyzer by the dialysate supply system. It does not include peritoneal dialysate. Such phrases as“dialyzing fluid” or“dialysis solution” may be used in place of dialysate.

3.6 dialysate supply system: Devices that prepare dialysate online from water and dialysis concentrate(s) or store and distribute premixed dialysate; circulate the dialysate through the dialyzer; monitor the dialysate for temperature, conductivity (or equivalent), pressure, flow, and blood leaks; and prevent dialysis during disinfection or cleaning modes. The term includes reservoirs, conduits, proportioning devices for the dialysate, and monitors and associated alarms and controls assembled as a system for the characteristics listed above. The dialysate supply system is often an integral part of single-patient dialysis machines (see normative reference 2.6).

3.7 dialysis concentrate: Fluid containing high concentrations of electrolytes. It is intended to be diluted with purified water to form dialysate. Dialysis concentrate comes in various formulations and concentrations (dilution ratios). It comes in liquid form or can be mixed at the point of use from powder or cartridges containing powder (see normative reference 2.3). It is referred to as“concentrate” throughout this document.

3.8 transmembrane pressure: As related to the dialysis machine, transmembrane pressure is the pressure difference between the blood compartment and dialysate compartment of the dialyzer.

4.1.1 Device markings

Each device shall exhibit the following markings:

1) name and address of manufacturer;

2) model and serial number;

3) operating controls labeled so as to minimize the possibility of misinterpretation of function;

4) proper labeling of displays, including design and scale, to enhance legibility; .

5) trade name of the product;

6) specific electrical information such as voltage, amperage, and relevant cautions and warnings; and

7) color-coded fluid pathway connectors.