ANSI AAMI ISO 14708-1-2014 pdf download

ANSI AAMI ISO 14708-1-2014 pdf download.Implants for surgery — Active implantable medical devices

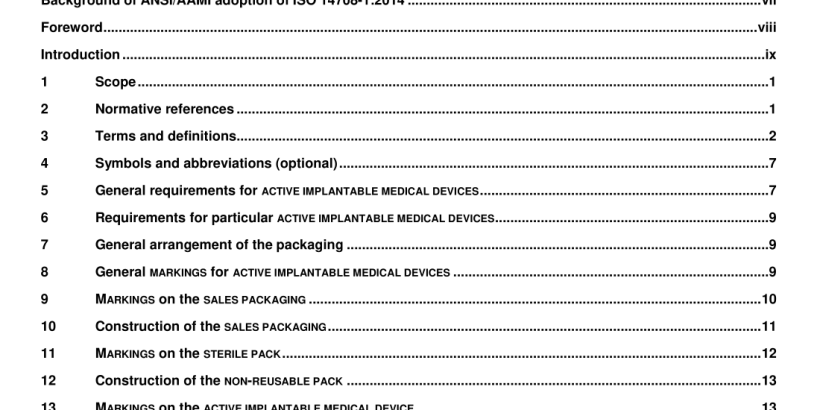

1 Scope

This part of ISO 1 4708 specifies requirements that are generally applicable to ACTIVE IMPLANTABLE MEDICAL DEVICES . NOTE 1 For particular types of ACTIVE IMPLANTABLE MEDICAL DEVICES , these general requirements are supplemented or modified by the requirements of particular parts of ISO 1 4708. The tests that are specified in ISO 1 4708 are type tests and are to be carried out on samples of an ACTIVE IMPLANTABLE MEDICAL DEVICE to show compliance. This part of ISO 14708 is applicable not only to active implantable medical devices that are electrically powered but also to those powered by other energy sources (for example by gas pressure or by springs). This part of ISO 1 4708 is also applicable to some non-implantable parts and accessories of the ACTIVE IMPLANTABLE MEDICAL DEVICES . NOTE 2 The device that is commonly referred to as an ACTIVE IMPLANTABLE MEDICAL DEVICE can be a single device, a combination of devices, or a combination of a device or devices and one or more accessories. Not all of these parts are required to be either partially or totally implantable, but there is a need to specify some requirements of non-implantable parts and accessories if they could affect the safety or performance of the implantable device. NOTE 3 In this part of ISO 1 4708, terms printed in small capital letters are used as defined in Clause 3. Where a defined term is used as a qualifier in another term, it is not printed in small capital letters unless the concept thus qualified is also defined. NOTE 4 The terminology used in this part of ISO 1 4708 is intended to be consistent with the terminology of ISO/TR 1 4283:2004.

14.1 Any implantable part of an ACTIVE IMPLANTABLE MEDICAL DEVICE or other parts enclosed in the NON – REUSABLE PACK (see 7.1 ) and not contained within an implantable, hermetically sealed, impermeable container shall be terminally sterilized. The sterilization PROCESS shall achieve the theoretical probability of there being a viable microorganism present on the content of the NON – REUSABLE PACK which shall be equal to or less than 1 0 −6 . Compliance is confirmed if the documentation and records provided by the MANUFACTURER demonstrate that the contents of the NON – REUSABLE PACK have been subjected to a validated sterilization PROCESS fulfilling the above- mentioned requirement. NOTE Examples for terminal sterilization PROCESSES are described in ISO 1 1 1 35-1 , ISO 1 1 1 37-1 , ISO 1 1 1 37-2, ISO 1 7665-1 , or ISO 1 4937.

14.2 Any part of the ACTIVE IMPLANTABLE MEDICAL DEVICE , intended in NORMAL USE to be in contact with body fluids shall cause no unacceptable release of particulate matter at time of implantation. Compliance is checked by a suitable test method for collecting and counting surface-born particulate matter. The following test for counting the number of particles of a particular size utilizes the light obscuration particle count test method. This method shall be used to resolve doubts or dispute. NOTE 1 This test is intended to evaluate the ability of the part of the ACTIVE IMPLANTABLE MEDICAL DEVICE to be cleaned as well as the particulates that can be transferred to the part from its immediate packaging. It does not evaluate the particulates that might be generated during handling of the packaged part such as during transport and storage. NOTE 2 The test is carried out under conditions limiting particulate contamination, preferably in a laminar-flow cabinet.

Testing of the particle-free water: Determine the particulate contamination in five samples of particle-free water, each of 5 ml, according to the method described below. If the number of particles of size 1 0 μm or greater exceeds 25 for the combined 25 ml, the precautions taken for the test are not sufficient. The preparatory steps shall be repeated until the environment, used equipment, and water are suitable for this test. Testing of the container: Fill the container that will be used for extraction (containing the mechanism that is needed for agitation) with 200 ml of particle-free water. Determine the particle counts as described in the measurement section below. Take five samples of each 5 ml. Count the number of 1 0 μm or greater size particles in each of the five samples.